EX058 ROP

Reorder Point Calculation

Using implemented functions, it is possible to calculate and update planning parameters related to the reorder point (ROP) and safety stock to optimize inventory levels.

The app’s features include:

- SKU Management

- Management via SKU allowing calculation differentiation by location

- 4 ROP calculation formulas

- 4 calculation formulas are provided that may or may not consider demand variability and/or lead time

- Reading forecast or scheduled orders

- Through appropriate setup, it is possible to consider the forecast or scheduled sales orders in parameter calculation

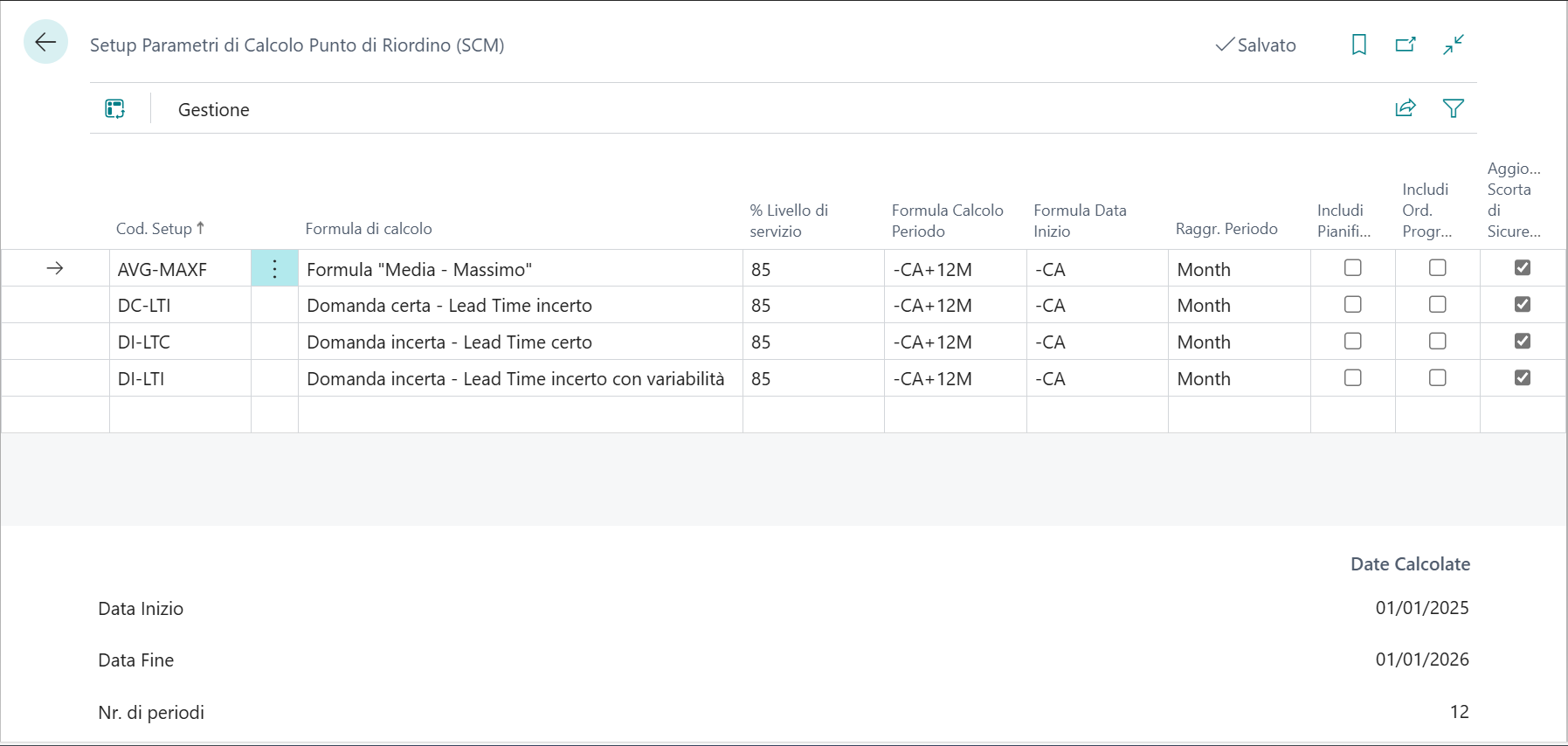

Reorder Point Calculation - Setup

Through a setup card, the formula to use and related input parameters can be defined.

The ROP setup code is assigned in the item or SKU master data to define the calculation rules for updating safety stock and reorder point if the item has a “Fixed reorder quantity” method.

By enabling the “include forecast” and/or “include scheduled orders” flags, the app considers the forecast defined in the setup or all scheduled sales orders as the historical series to analyze.

If the “safety stock” flag is active, the procedure calculates and updates the safety stock.

The service level corresponds to the Z parameter in the formulas.

The grouping period defines the period within which the system will sum all movements.

The Start Date Formula defines the start date of the periods to consider in the historical series. The End Date Formula defines the end date of the period.

At the bottom of the page, the dates are shown based on the work date.

Reorder Point Calculation - Formulas

If SKUs are present, the procedure performs calculations by splitting the historical series by location, calculating differentiated values for each SKU.

In the “Replenishment” tab of the item and SKU master data, the calculation setup card assignment is present.

Reorder Point Calculation - Formulas

Below is the detail of the formulas that can be assigned to each ROP setup.

Reorder Point Calculation - Calculation Report

The calculation is performed using the following schedulable report:

- If the flag is disabled, the report considers the input parameters defined in the ROP setup card.

- If the flag is enabled, the parameters in the master data setup card are overridden by those entered in the report page.

Reorder Point Calculation - Batch

The calculated values from the procedure are reported in a batch, allowing them to be confirmed to update the master data.

The batch shows various calculation-related information and allows value modification before registration.

If the item is managed via SKU, the calculation is split by location and the batch suggests the reference location.

Once the calculated values are verified, they can be confirmed using the registration button to update the master data.

The ROP calculation can also be executed using the ROP calculation button.

Additionally, the page of historical movement changes can be accessed.

Feedback

Was this page helpful?

Glad to hear it! Please tell us how we can improve.

Sorry to hear that. Please tell us how we can improve.