Inventory WIP calculation

Inventory WIP calculation

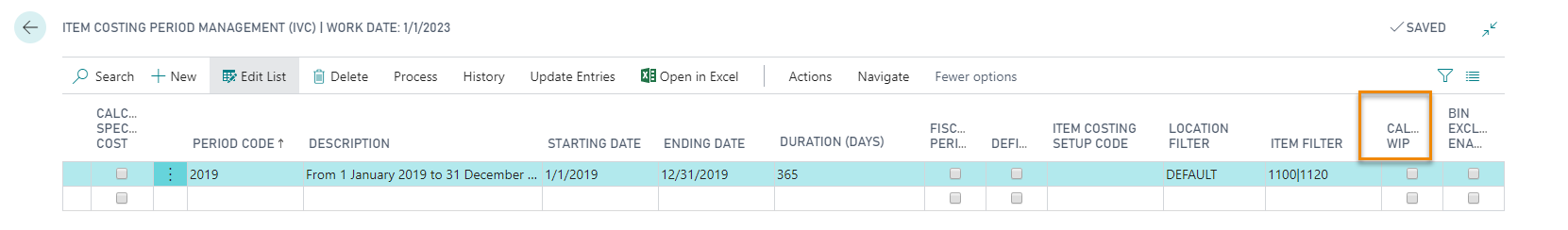

Setup: to perform the WIP calculation it is necessary to activate the “Calculate WIP” flag for the period being processed:

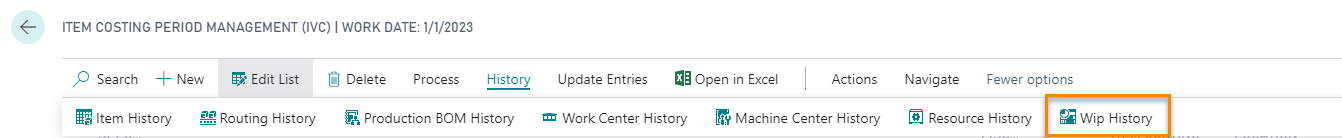

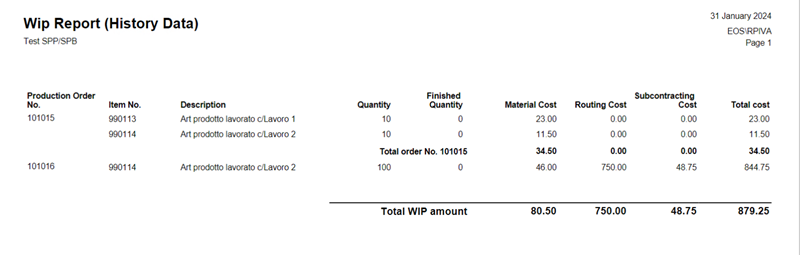

Processing: after having performed the “Archive Period Data” and “Calculate Actual Data” functions, you can access the “Wip history”:

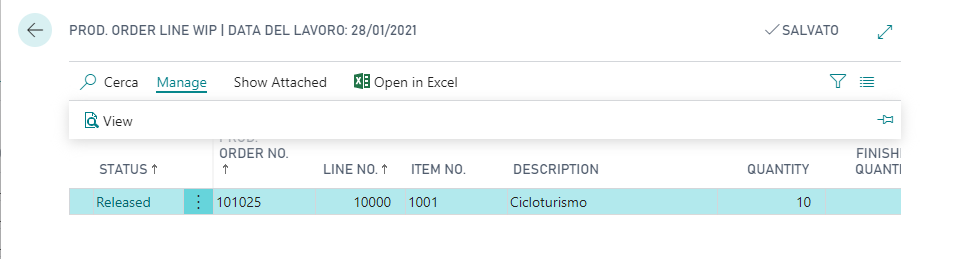

All production orders included in the calculation are shown and, through Manage-> View, you can access the detail card of the single order.

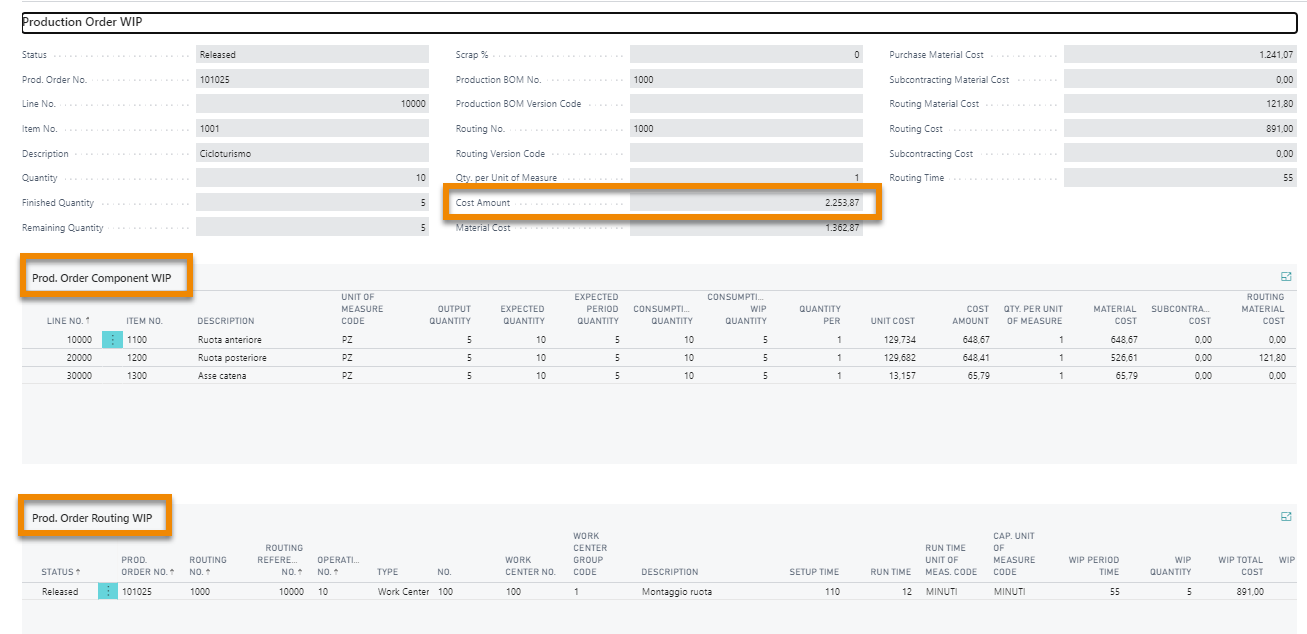

- The “Cost Amount” field in the header indicates the WIP value calculated for the specific order.

- “Prod. Order Component Wip” Tab: contains the enhancement of the components used for items not yet stocked in the warehouse as Output (partially or completely). In the example above : 10 pieces were consumed for each component but partial output was recorded (5 out of 10 pieces).

- Prod. Order Routing WIP” Tab: contains the enhancement of the capacity movements (run time + setup time) recorded for items not yet stocked in the warehouse as Output (partially or completely). In the example above : Capacity accounting entries were recorded for 122 minutes (total expected to produce 10 pcs) but a partial Output was booked in the warehouse (5 out of 10 pcs). Generally for internal machining, the calculation is carried out according to the declared / actual times, for the Subcontracting according to the pieces.

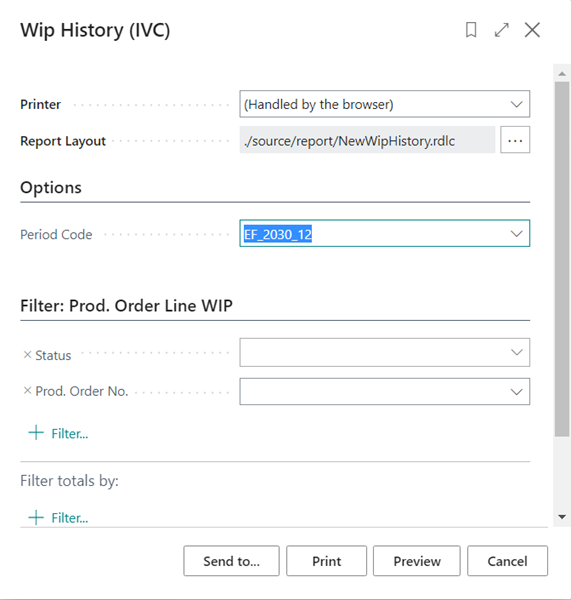

Wip History (IVC)

The calculated data can be viewed through the Wip History (IVC) report:

Feedback

Was this page helpful?

Glad to hear it! Please tell us how we can improve.

Sorry to hear that. Please tell us how we can improve.

EOS Labs -