Material status

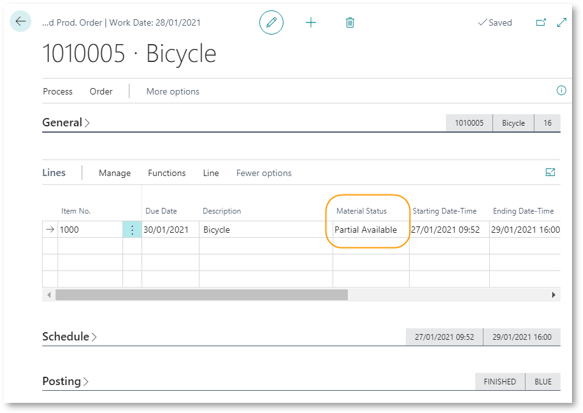

The Material Status feature gives you an information of the material availability of each production order.

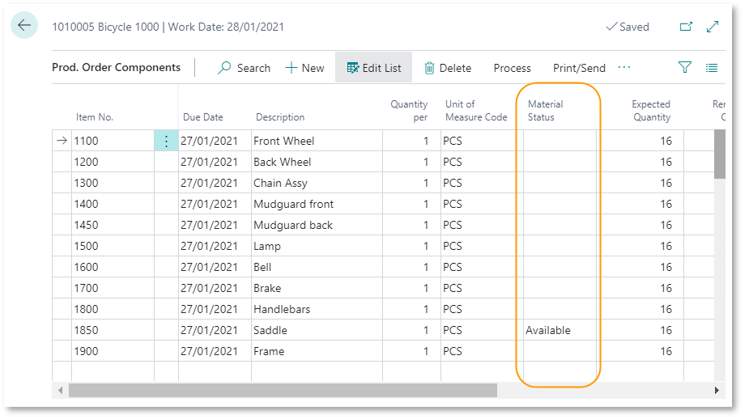

The Material Status is calculated for each component of a production order (only for firm planned and relased orders).

Available: completely available

Partially available: not completely available

Blank: not available

You can launch the calculation of the Material Status, from the Sequence Planning or from the Planning Setup. The Material Status is shown on each production order and on the Sequence Planning.

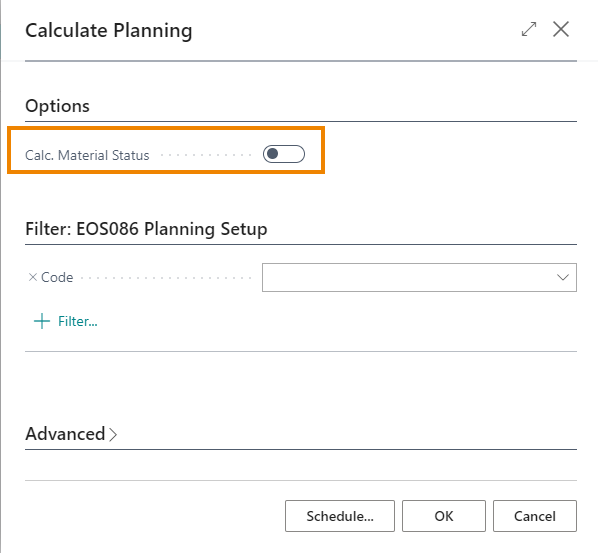

On the Planning setup (MPL) from Related->Planning calculation it is possible to execute the planning according to the setup set and it is also possible to calculate the Material Status.

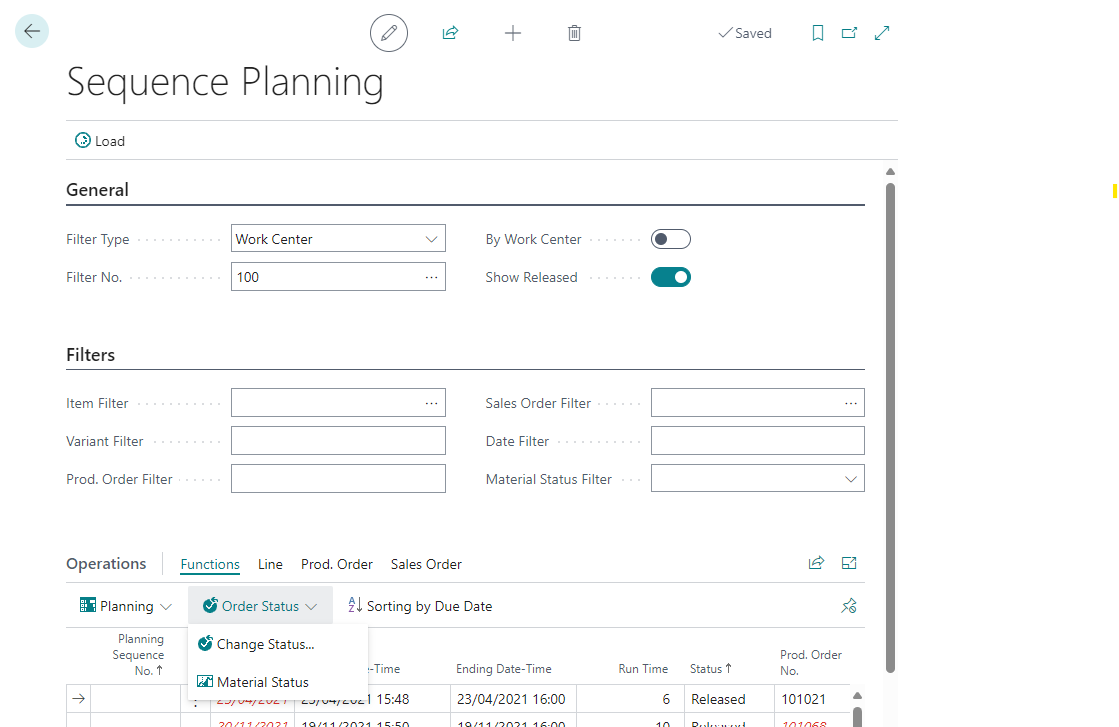

Calculation of material status from Sequence Planning

The material status is calculated based on availability and not based on stock.

When using the function on the Sequence Planning page: from Functions->Order Status->Material Status

options are present

All: the material status is calculated for all firm planned and released production orders (planned ones are not considered).

Selected Lines: is calculated only for the selected operations (the related production orders).

The material status calculation has the following priorities:

Released orders have higher priority, firm planned orders are later.

If the warehouse is used and a pick has been made for a released order, then this order has the highest priority

Feedback

Was this page helpful?

Glad to hear it! Please tell us how we can improve.

Sorry to hear that. Please tell us how we can improve.