Sequence Planning (MPL)

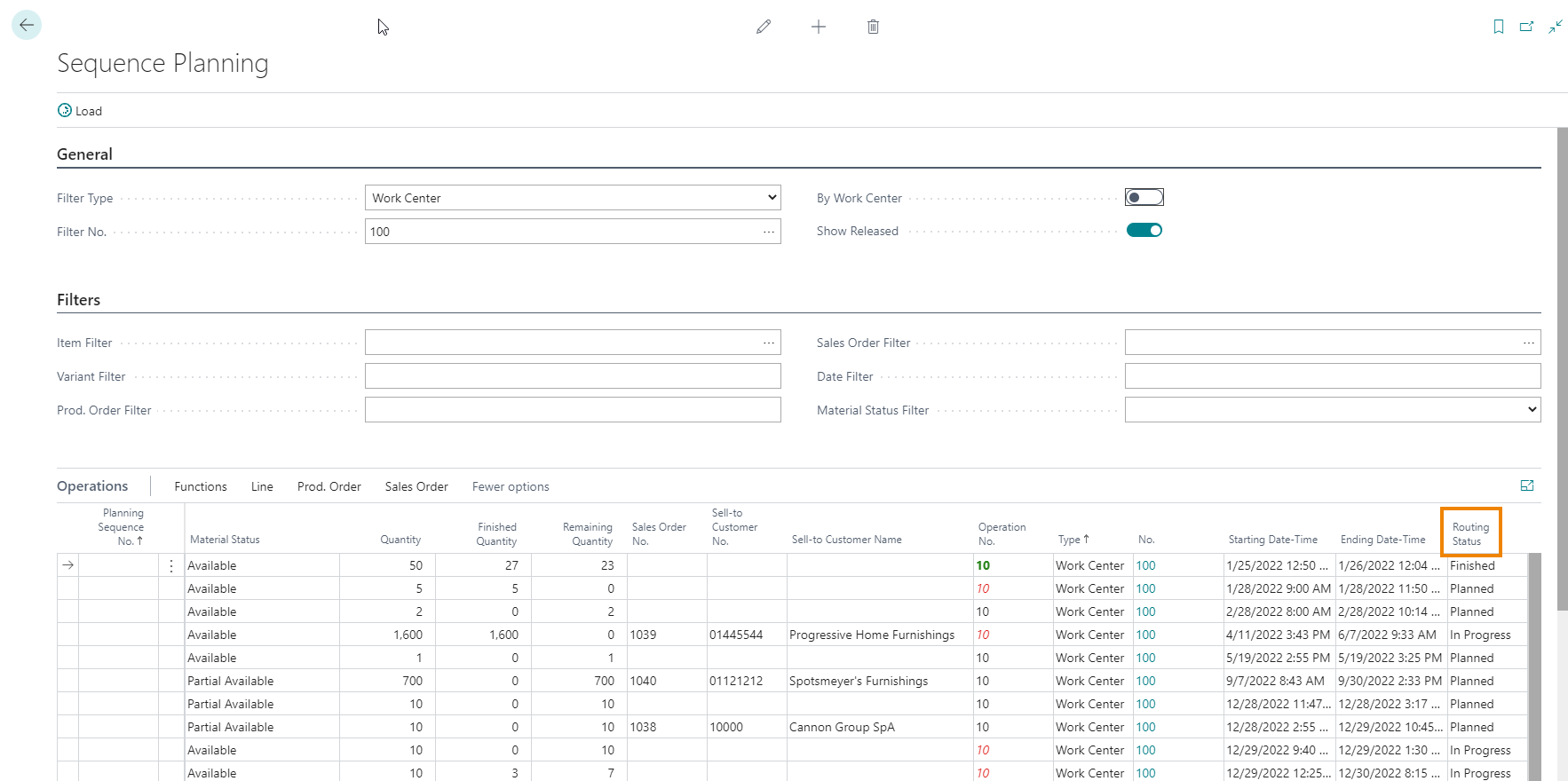

The Sequence Planning page shows all operations of a Work Center or Machine Center, and allows the sequencing of the single operations. Each operation can be monitored by its Routing Status (planned, in progress, finished). You can give each operation a production sequence number, this can be done manually or by replanning the operations.

The operations shown on the Sequence Planning page, can be set by various filter criteria.

| General | Description |

|---|---|

| Filter Type / Filter No. | it is possible to filter by a specific Work Center or Machine Center |

| By Work Center | if activated, then all operations for the specific Work Center are shown, also those who are on a Machine Center related to the specific Work Center |

| Show Released | if you enable it, you include also the operations of released production orders, otherwise only those of planned and firm planned orders are shown |

| Filters | Description |

|---|---|

| Item Filter | shows all operations related to a production order with the specific item |

| Variant Filter | shows all operations related to a production order with the specific variant |

| Prod. Order Filter | all operations of the production orders in the filter criteria |

| Sales Order Filter | all operations related to sales orders |

| Date Filter | applied to Starting Date of the operations to filter |

| Material Status Filter | shows all operations that corresponds to the Material Status (Partial Available, Available) |

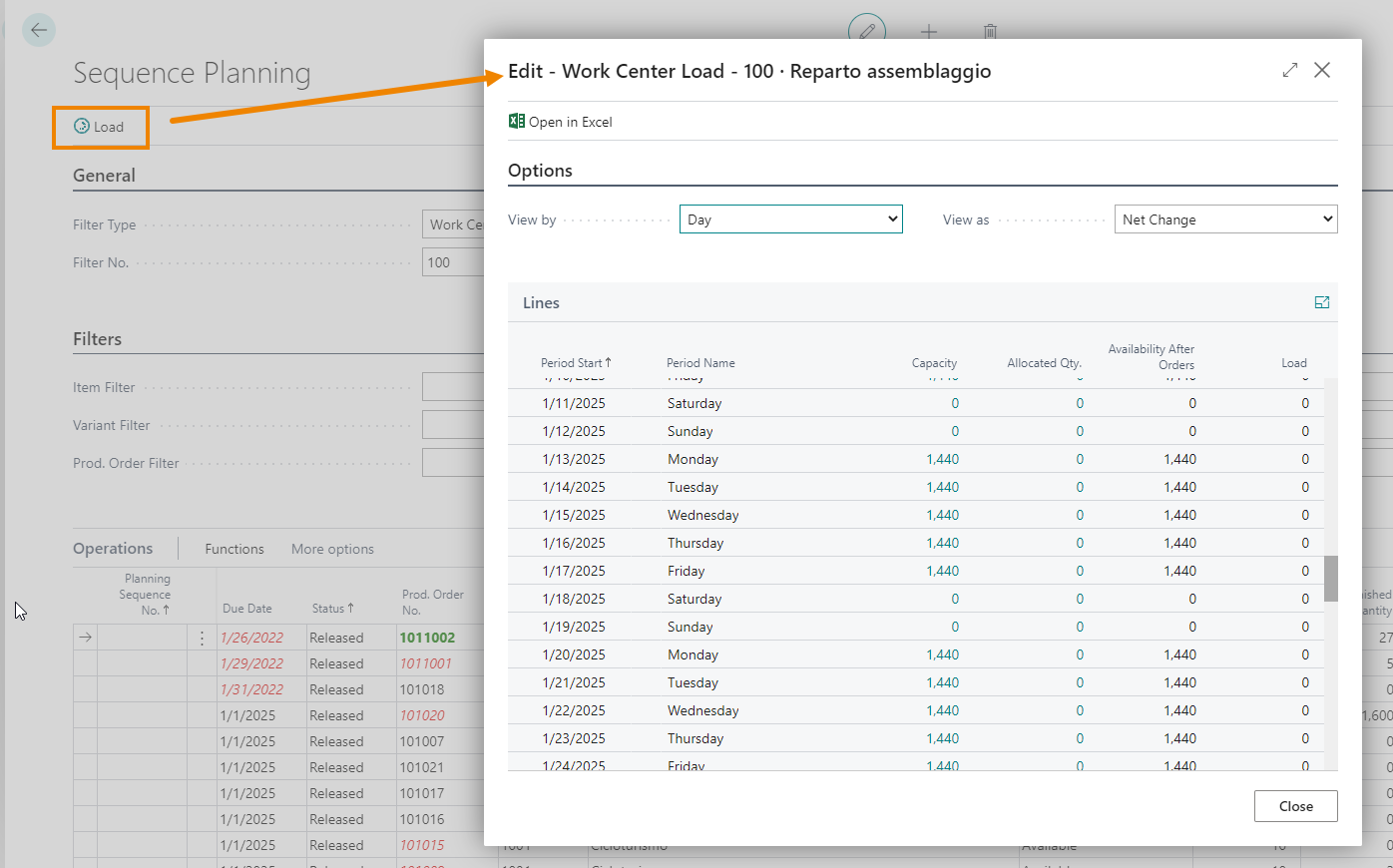

Pressing Load you can view the avaliability of the machine or work center, including its capacity, the allocated quantity, avaliability after orders and the load in percent of its total capacity:

Operations

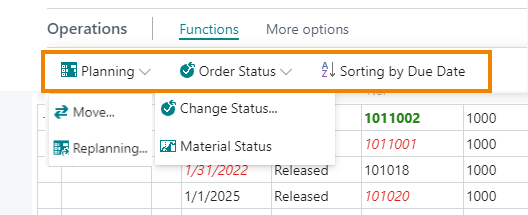

On the Sequence Planning page, on the Operations Tab, there are various functions in order to plan the operations:

| Name | Description |

|---|---|

| Sorting by Due Date | sorts the operations by Due Date of the related production order |

| Move | moves the selected operations to a Machine Center of the current Work Center |

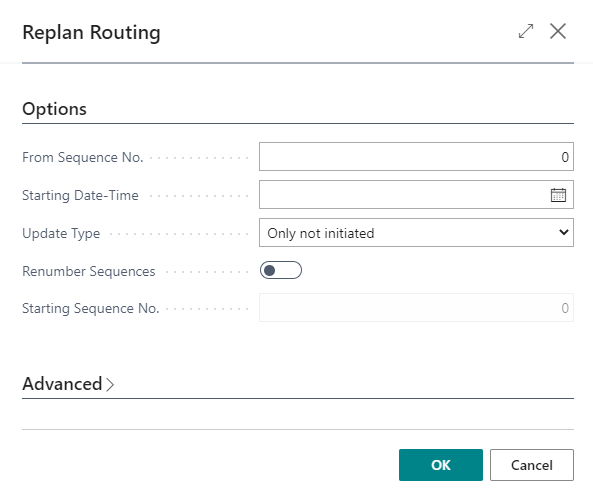

| Replanning | brings the selected operations in sequence, the sequencing is doing by a finitely forward scheduling from the starting date-time. While replanning the operations, you can choose to renumber the sequences of the operations. Usually only not initiated operations are handled, these are all operations which Routing Status is planned, to change this behaviour you can set the Update Type field on the request page to All. |

| Change Status | the Planning Sequence allows to quickly change the production order status of all selected operations |

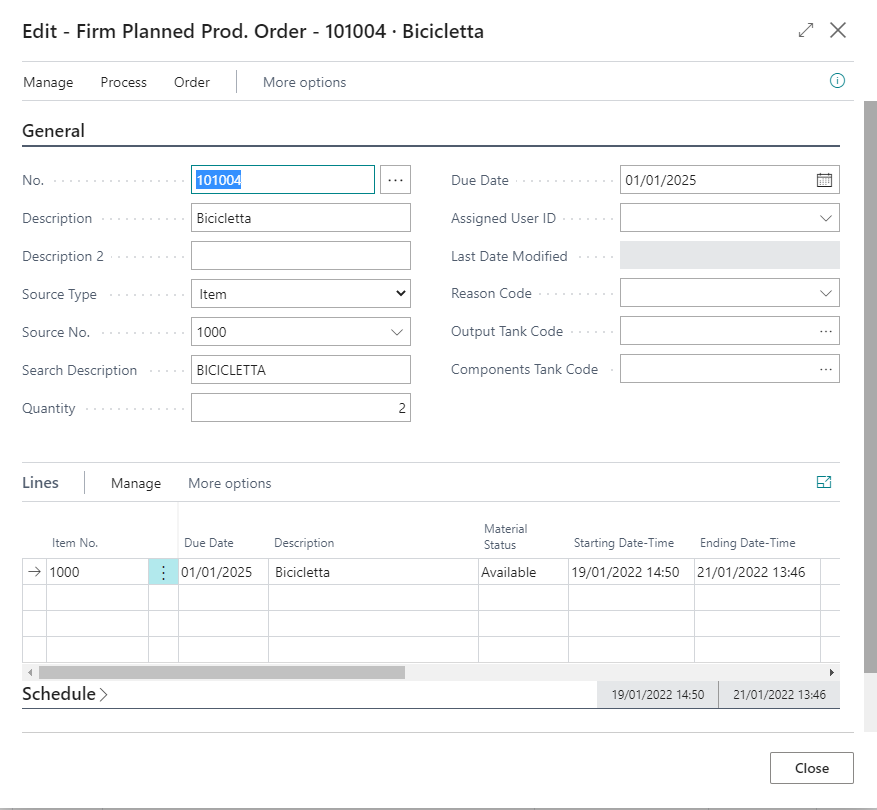

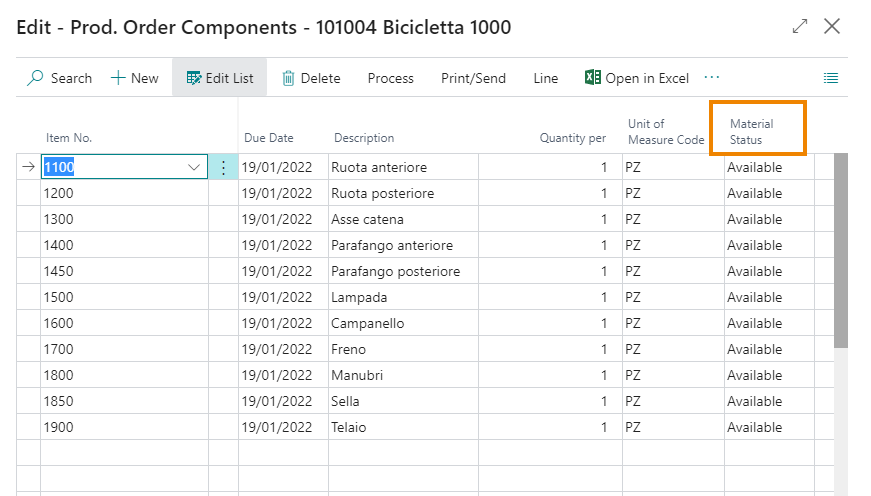

| Material Status | from the Planning Sequence you can recalculate the Material Status for all production orders of the selected operations. It gives you an information of the material availability of each production order. The Material Status is calculated for each component of a production order (only for firm planned and relased orders). You can launch the calculation of the Material Status, from the Sequence Planning or from the Planning Setup (see on next chapter). The Material Status is shown on each production order and on the Sequence Planning.   |

Blanket Purchase Orders

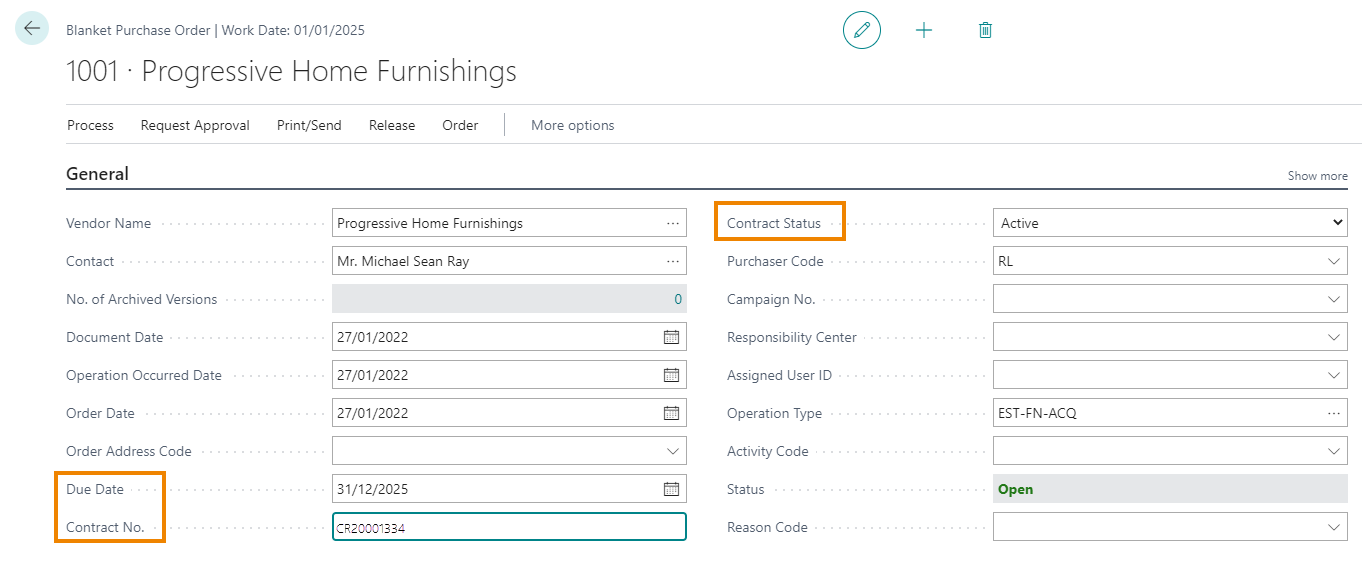

Blanket Purchase Orders are also known as vendor contracts.

You can integrate them into your planning result, when you convert the planning suggestion into a purchase order, then the contract references are also transferred to the purchase order.

On the Blanket Purchase Order you can set the following information:

Due Date: until the contract is valid

Contract No.: number of the contract established between you and the vendor

Contract Status: only Active contracts are considered in the planning results

Planning Setups (MPL)

You can use the Planning Setup to define a planning workflow, for instance:

MPS and MRP planning of all items

Split and distribute the planning result to dedicated planning worksheets

Schedule the planning calculation from Job Queue

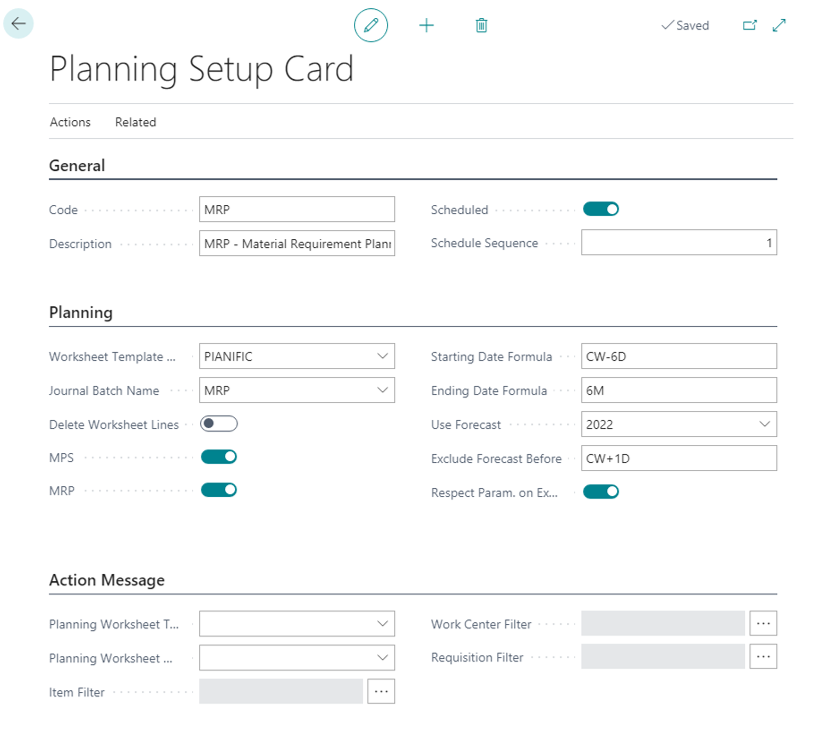

Planning Setup – Calculation

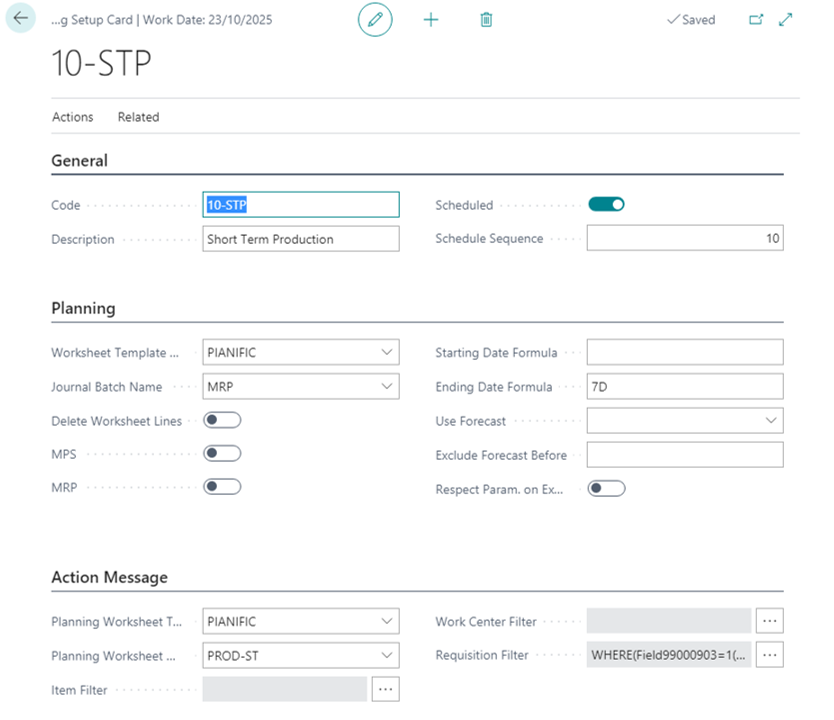

You define a Planning Setup either for the planning calculation or for the split of the planning result. In both cases you must define a specific Worksheet. In the picture you can see an example for a setup to do a planning calculation:

The calculation result is written into the worksheet defined by Worksheet Template Name and Journal Batch Name

MPS and MRP are calculated

The starting date is calculated by the Starting Date Formula, in this example it‘s always Monday of the current week The ending date is calculated by the Ending Date Formula

If you would consider an item filter for the calculation, then you could do this by the Assist button of the Item Filter field on the Action Message register

On the Planning Setup Card you can set the same parameters as on the planning calculation batch (planning worksheet).

Planning Setup – Split

To split the planning result into another worksheet, you must define the worksheet where the results come from, and the worksheet where the results should be transferred to.

On Worksheet Template Name and Journal Batch Name fields you define the worksheet where the results come from.

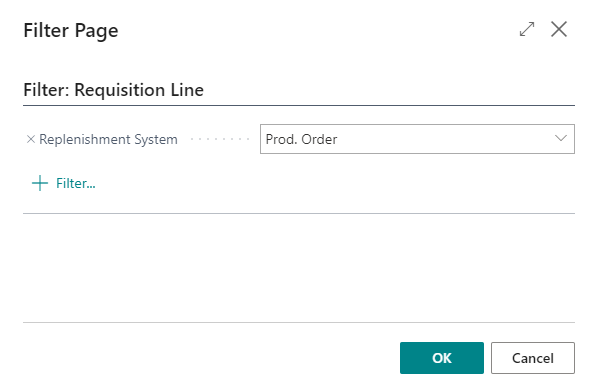

On the Planning Worksheet Template and Planning Worksheet Name fields you define the target worksheet. On the Requisition Filter field you can define a filter depending on which data should be transferred, e.g. “Replenishment System equal to Prod. Order”.

If the Starting Date Formula and/or Ending Date Formula fields are specified, then the data to transfer are filtered accordingly to the Due Date.

Planning Setup - Schedule

To perform the calculations defined on the Planning Setup in an automatic way, you can add Report 70491929 “EOS086 Calculate Planning” to the Job Queue.

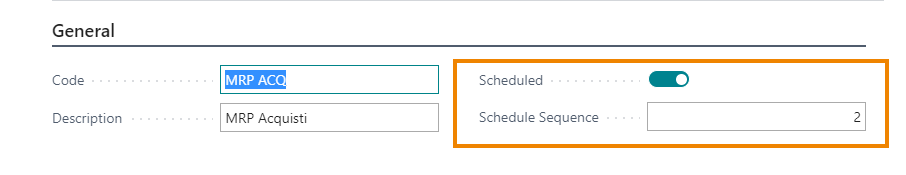

For each Planning Setup you must setup the fields Scheduled and a Schedule Sequence. The Schedule Sequence gives the sequence to perform the related calculation, this is important because firstly all the calculations must be done and then the splits are processed.

Calculate Planning (MPL)

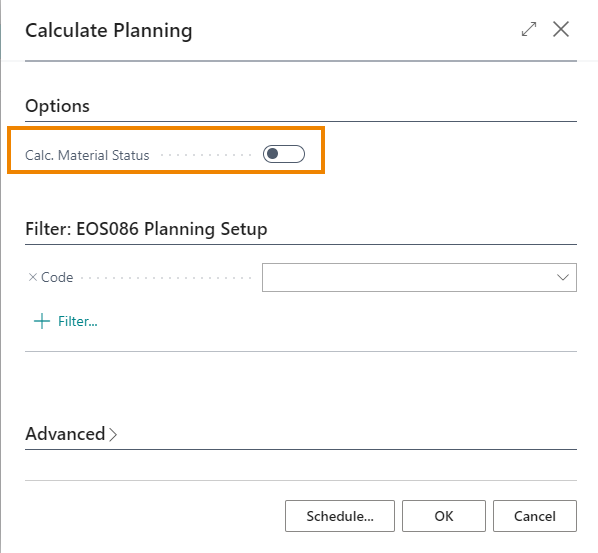

On the Calculate Planning batch (Actions->Calculate Planning) you can specify to calculate also the Material Status.

Feedback

Was this page helpful?

Glad to hear it! Please tell us how we can improve.

Sorry to hear that. Please tell us how we can improve.