Setup

The Packaging Setup (HUM) contains a series of parameters to set for using the app. The fields related to the packing list are the following:

| Campo | Descrizione |

|---|---|

| Packaging Instruction Calculation | Set the implementation of the packaging calculation engine. The field can be extended to make a custom calculation. |

| Inventory Check Policy | Indicates the way HU inventory checks are performed when posting item entries. If you only use the Packing List app, it is a good idea to set it to None. |

| Packing List Suggestion | Specifies how and if different suggestion methods can be selected when suggesting a packing list. It is recommended to set the value to Fixed. Legacy value is the previous calculation method. |

| Packing List Suggestion Calculation | Specifies the packing list suggestion method. This is only applicable if the suggestion policy is Fixed. The field can be extended to make a custom calculation. |

| Enable Assignment Packing List for Source Line | Enables the assignments on the Packing List for the selected source line. The feature can only be used with the Packing List app and using the assignment made on the dedicated page for adding content. |

| Transfer Outbound Handling Units | The field has been made obsolete and replaced by the new field: Handling Unit Mgt. in Transfer order. |

| Handling Unit Mgt. in Transfer order | Specifies how to manage the outbound Handling Units in Transfer order. The allowed values are: Default. It is the old way of managing handling units that does not provide for the automatic assignment of the same. To be used, for example, in case there are customs. Transfer Outbound HU. Allows the transfer of handling units from the transfer-from (outbound) location to the transfer-to location (Inbound). Handling units are assigned to the transfer order if the transfer-to location does not require the warehouse receipt, otherwise they are assigned in the creation of the warehouse receipt from the transfer order. Ship Outbound HU. Change the status to “Shipped” and empty handling units when a transfer shipment is posted. |

| Packing List Report No. | Specifies the value of the “Packing List Report No.” field. The default report for the app is 70491920. |

| Weight Calculation | Specifies the calculation method to use for total weights. Allowed values are: Content+Container, Container. |

| Rounding Direction | Rounding Direction of the quantity in the Packing List suggestion. The allowed values are: Round up, Round down |

| Volume Conversion Factor | The Item Volume will be divided by this value to achieve conversion to cubic meters (m³). |

| Volume Rounding Precision | The Item Volume will be rounded for this decimal value; for example the value 0,001 specifies three decimal places. The default is five decimal places. |

| Packaging Material Nos. | Insert the default number series for packaging materials. |

| Packaging Instruction Nos. | Insert the default number series for packaging instructions. |

Packaging Instructions

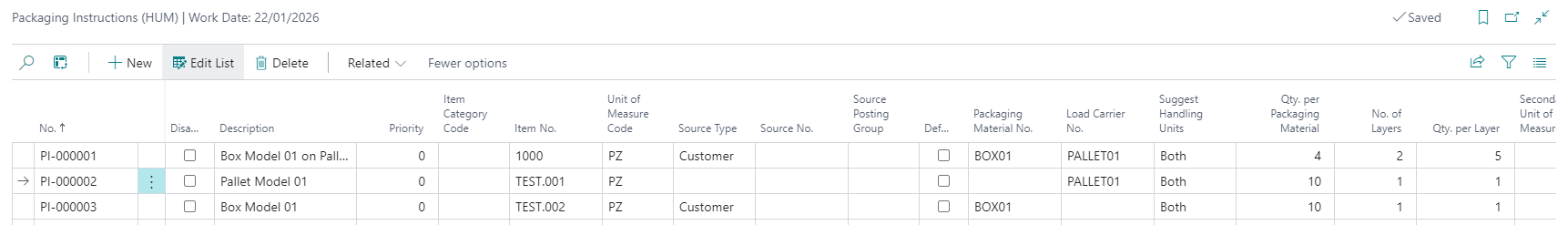

In order to use the “Suggest Line For Packing” function, you must fill in a setup in “Packaging Instructions”. This setup provides the system with the information to create the packaging for each different item:

| Field | Description |

|---|---|

| No. | Packaging instructions No. |

| Disabled | You can enable or disable the row after creation. |

| Priority | You can prioritize the row by indicating numeric values. The highest has top priority. |

| Item Category Code / Item No. / Variant Code | Indicate the item or the item category code or item variant. |

| Unit of Measure Code | Insert the unit of measure of the packed item, f.e. box. |

| Source Type | You can choose between Customer/ Vendor / Salesperson / Output and optionally select a Number and a Posting Group. |

| Default | Specify the instruction as default for the item and source combination. |

| Packaging Material No. | Insert the packaging material used to pack the item. |

| Load Carrier No. | Insert the load carrier used to pack the item. |

| Qty. per Packaging Material | Quantity per packaging material (e.g. 20 pcs per box). If the instruction does not specify a packaging material but only a load carrier, the quantity per load carrier is intended. |

| No. of Layers | Number of layers in which the packaging materials are arranged inside the load carrier. If the instruction does not contain a packaging material, indicate the number of layers in which the items are arranged in the load carrier. |

| Qty. per Layer | Number of packaging material for each layer of the load carrier. Use only if the instruction contains both packaging material and a load carrier, otherwise set to 1. |

| Suggest handling units | Specifies which handling units are created during suggestion of the packing list for this instruction. |

| Secondary unit of measure code | Specifies a secondary unit of measure that is calculated in addition to the default quantities. |

| Secondary unit of measure factor | Specifies a secondary unit of measure factor that is calculated in addition to the default quantities. |

| Mandatory | When set, then a packaging must be specified on the shipment |

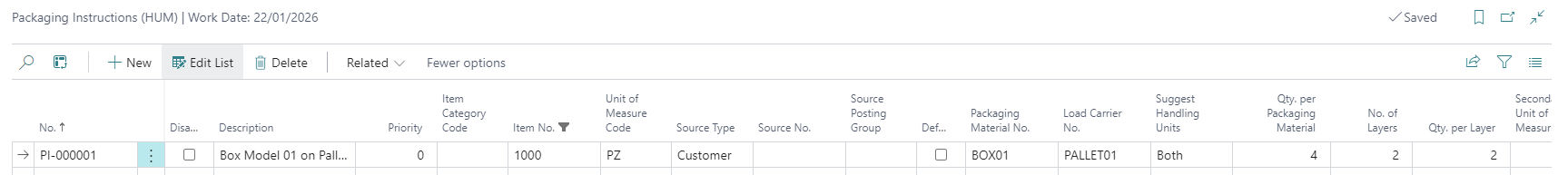

For example, entering a sales line for item 1000 with quantity 20 with the following packaging instructions:

- Packaging material BOX01.

- Load carrier PALLET01.

- Quantity 4. This means that in each BOX01 there are 4 units of item 1000.

- Nr. of layers 2. Load carrier PALLET01 has two layers.

- Quantity for layer 2. That means that for each layer there are 2 BOX01. for a total of 4 BOX01.

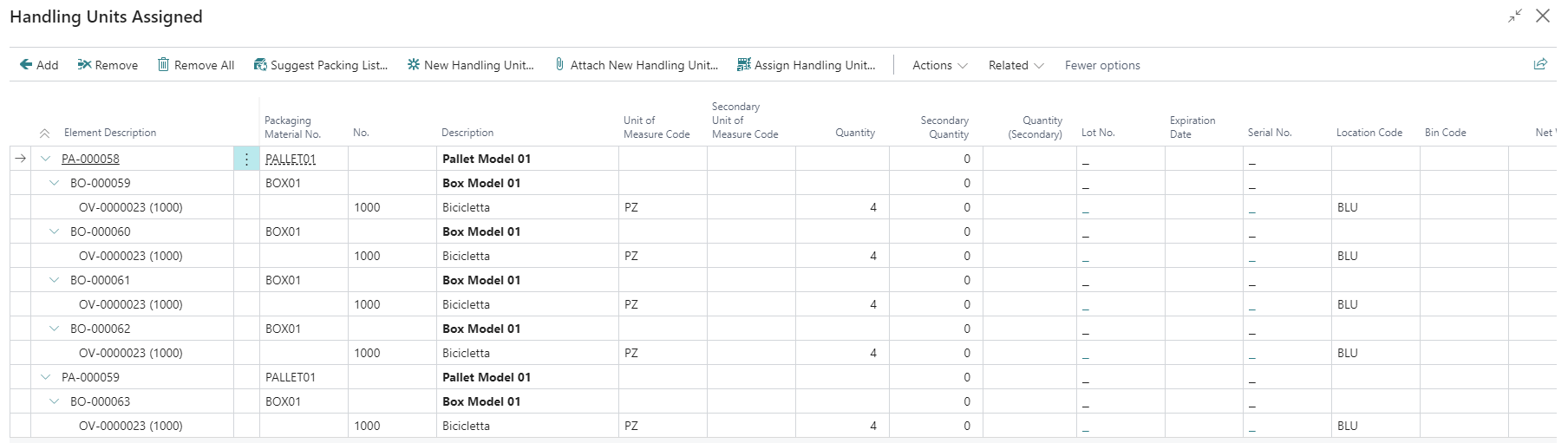

I get the following packing list calculation:

- 2 PALLET01.

- 5 BOX01.

- 20 units of item 1000.

- The first PALLET01 is complete and therefore contains 4 BOX01 and 16 units of item 1000.

- The second PALLET01 instead contains the remaining, that is 1 BOX01 with 4 units of item 1000.

Feedback

Was this page helpful?

Glad to hear it! Please tell us how we can improve.

Sorry to hear that. Please tell us how we can improve.

EOS Labs -