Packing List - SUMMARY

Press ALT + Q and digit “HUM” for a list of the involved functionalities:

Packing List Page

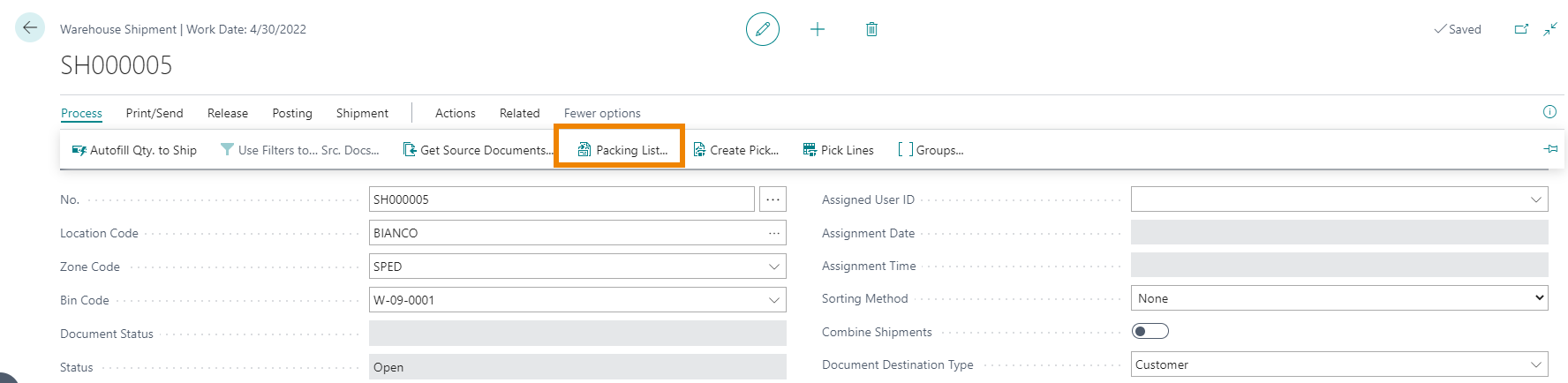

From a shipment/order you can open the Packing List composition page through Actions->Functions->Packing List or from Process->Packing List:

The Packing List is a set of handling units, connected to order lines, and has a tree structure.

First, you must select the handling units from “New Handling Unit”.

Clicking on New Handling Unit the system will open the list of packaging materials:

For example, we choose a box and then add content from Add Content .

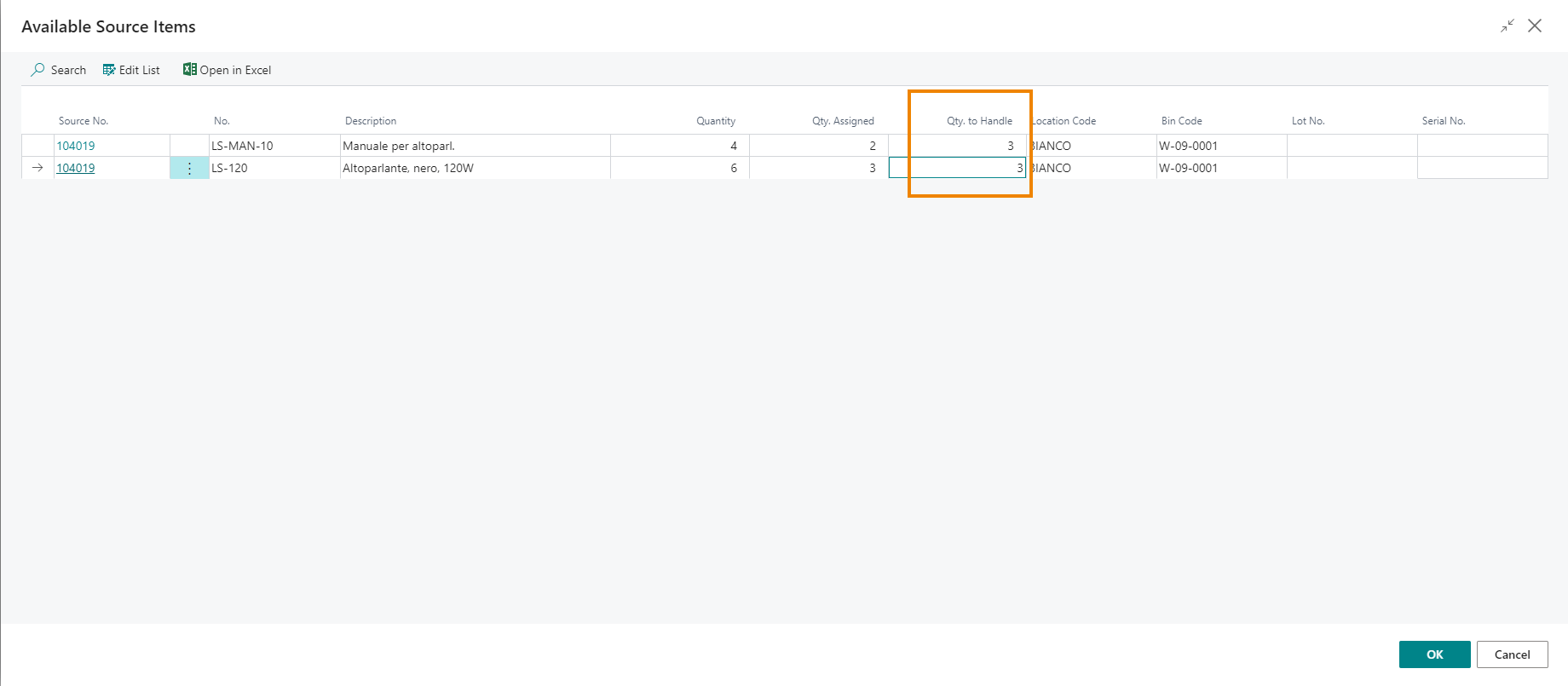

The page shows item lines based on orders/shipments. We enter quantities for the items to be added and press OK.

| Field | Description |

|---|---|

| Source No. | order number |

| No. | item number and description |

| Quantity | item quantity requested on the order page |

| Q.ty Assigned | quantity already assigned on the packing list |

| Q.ty to Handle | enter the quantity to be included in the box that we have selected in the packing list |

| Location Code | connected to the logistics flow of handling units |

| Bin Code | connected to the logistics flow of handling units |

| Lot No. | assign the lot number if needed |

| Serial No. | assign the serial number if needed |

| To create multiple containers in the same Packing List, you always proceed from New Handling Unit and then define its contents from Add Content. |

Tree Structure

If we want to add a larger container e.g. a Pallet, we can do it both before and after creating the Packing List.

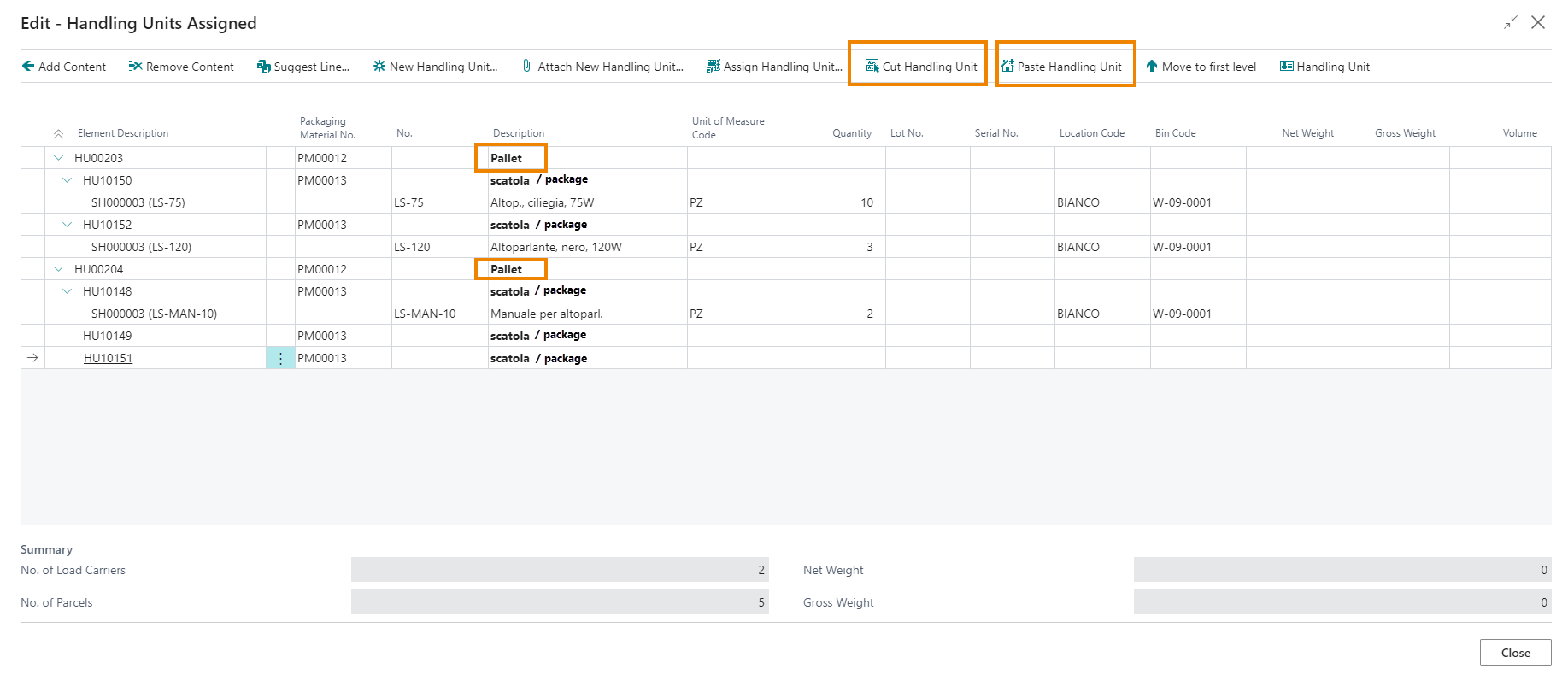

After entering it from New Handling Unit, through the Cut/Paste functions we can define the tree structure: we select the line of the package to be inserted on the pallet, we press Cut Handling Unit and then we select the pallet and press Paste Handling Unit:

| Action | Description |

|---|---|

| Cut Handling Unit | select the handling unit to put on the pallet |

| Paste Handling Unit | assign the handling unit to the pallet |

| Move to first level | disconnects the unit from the pallet and brings it back to its initial level |

| Attach New Handling Unit | as the “New Handling Unit” feature is used to generate a new unit. In this case, however, it will already be assigned to the selected pallet. |

| Remove Content | After selecting multiple lines, you can delete them from the packing list that you created. Note: if we remove a container, automatically all its contents are also deleted. |

| Assign Handling Unit | it opens a list of handling units that are already structured, and are not linked to any document and you can put them into the packing list (e.g. if pallets are prepared at one point in the Company and shipments subsequently take place at another point) |

| Suggest LIne For Packing | the system examines shipments and, according to the Packaging Instructions, proposes boxes already filled with the number of pieces indicated in setup |

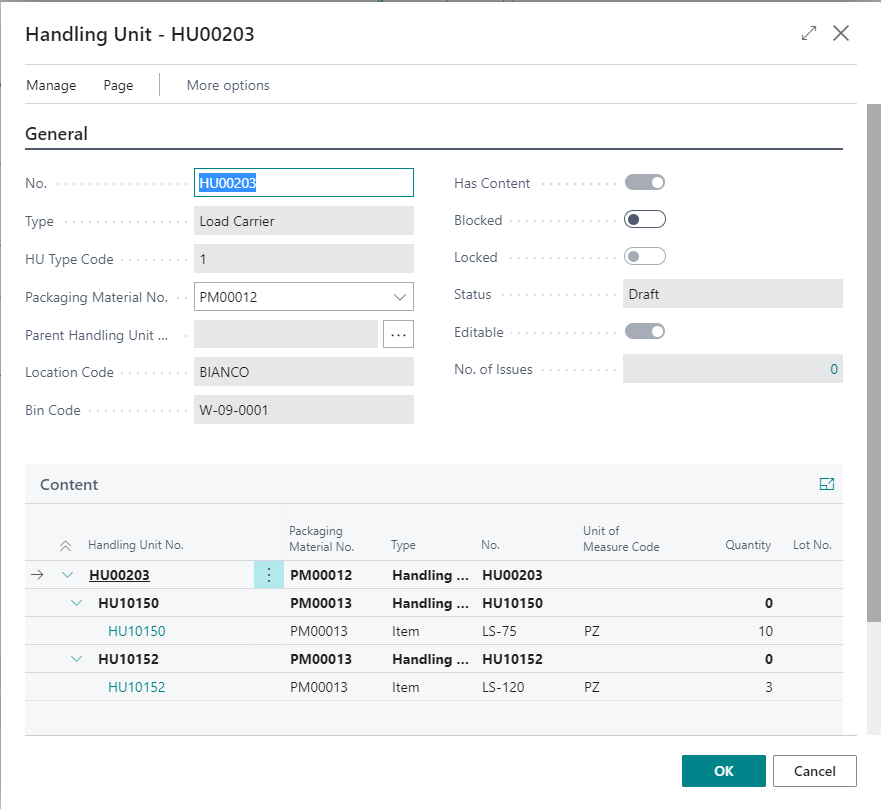

| Handling Unit | the system shows details about the selected unit and its contents |

To print the Packing List, from the document page click Actions->Print Packing List

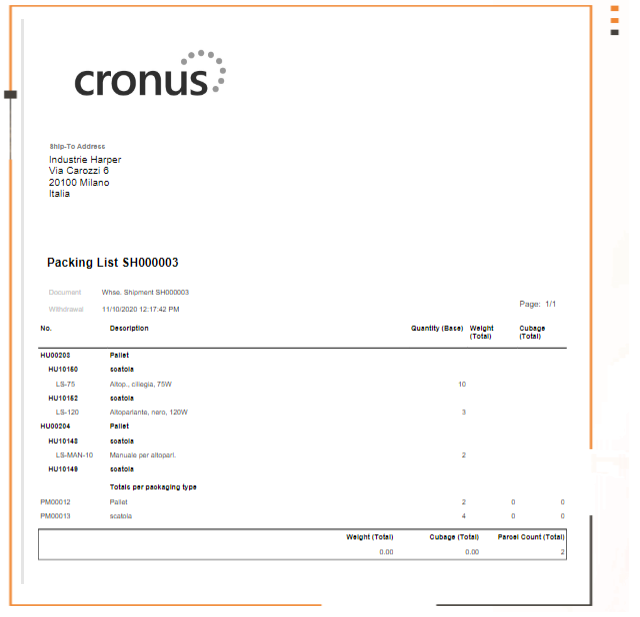

Example:

Transfer Order

In previous versions, a field called Transfer Outbound HU was inserted in the Packing Setup to enable the transfer of outbound handling units after a transfer shipment is posted, but this field has been deprecated and replaced by the Handling Unit Mgt. in Transfer order field. The allowed values are as follows:

- Default. It is the old way of managing handling units that does not provide for the automatic assignment of the same. To be used, for example, in case there are customs.

- Transfer Outbound HU. Allows the transfer of handling units from the transfer-from (outbound) location to the transfer-to location (Inbound). Handling units are assigned to the transfer order if the transfer-to location does not require the warehouse receipt, otherwise they are assigned in the creation of the warehouse receipt from the transfer order.

- Ship Outbound HU. Change the status to “Shipped” and empty handling units when a transfer shipment is posted.

The Handling Unit Mgt. in Transfer order field is present in the following tables:

- Packaging Setup (HUM). It represents the default at the company level.

- Transfer routes. For each transfer route, it is possible to define different ways of managing the load units.

- Transfer Order Header. When creating the transfer order header, if a transfer route exists for the selected locations, the value is taken from this table, alternatively from the Packaging Setup (HUM). For the individual transfer order, the user can manually change the value.

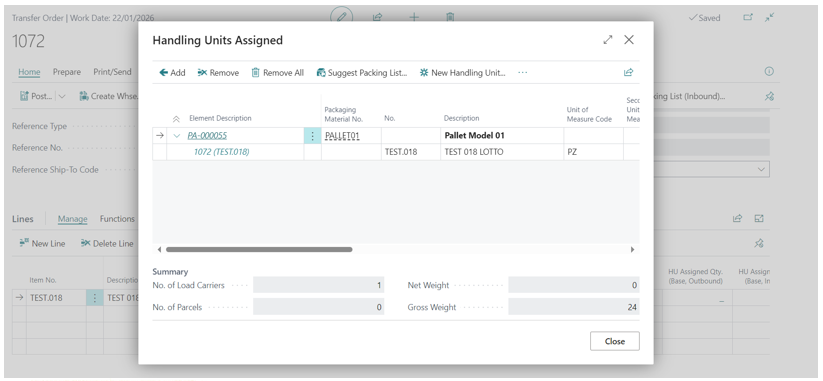

If the value of Handling Unit Mgt. in Transfer order field in transfer order is Default, the handling units are not transferred from the transfer-from location to the transfer-to location. The assignment must be done manually through the actions in the header of the transfer order.

If the value of Handling Unit Mgt. in Transfer order field in transfer order is Transfer outbound HU, the handling units are automatically transferred from the outbound location to the inbound location. In two different ways, depending on whether the inbound location is managed through warehouse receipt or not. If the inbound location does not have warehouse receipt, the handling units are automatically assigned after the transfer shipment is posted:

If the inbound location has warehouse receipt, the handling units are assigned when the warehouse receipt is created by the transfer order. If the warehouse receipt is created from the warehouse receipt page, a new function called Assign HUs for Transfer Orders is available, which allows to assign the corresponding handling units once the transfer lines have been selected.

After the receipt has been registered, however it occurs, the handling units will be in the loaded state and will be located at the inbound location/bin code:

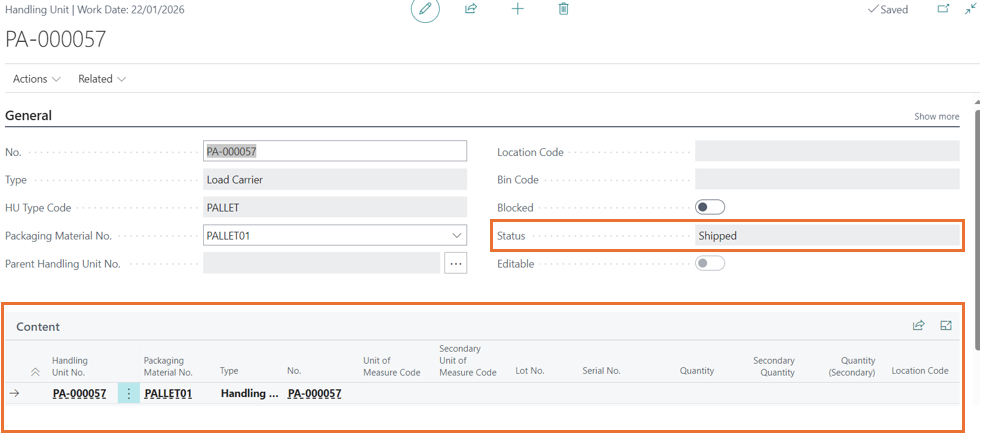

If the value of Handling Unit Mgt. in Transfer order field in Transfer Order is Ship outbound HU, after the shipment of the transfer order is posted, the handling units are emptied and their status changes from Loaded to Shipped.

Feedback

Was this page helpful?

Glad to hear it! Please tell us how we can improve.

Sorry to hear that. Please tell us how we can improve.