Maintenance Point

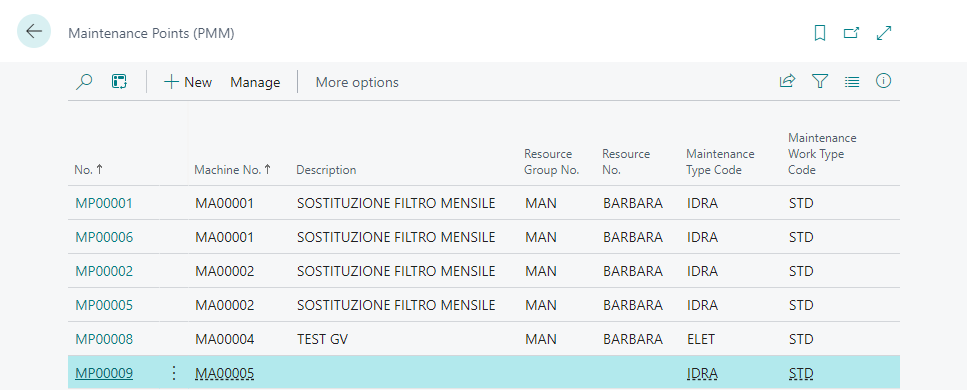

You can manage machine maintenance points through the “Maintenance Points (PMM)” page.

Maintenance points are used to automatically generate work requests, which can be created based on:

- Automatic (a new work request is created after the completion of the previous one).

- Schedule (e.g. every day, week, month, year etc.).

- Planning criteria (e.g. every 10.000 pieces produced etc.).

Learn more about automatic work request creation rules.

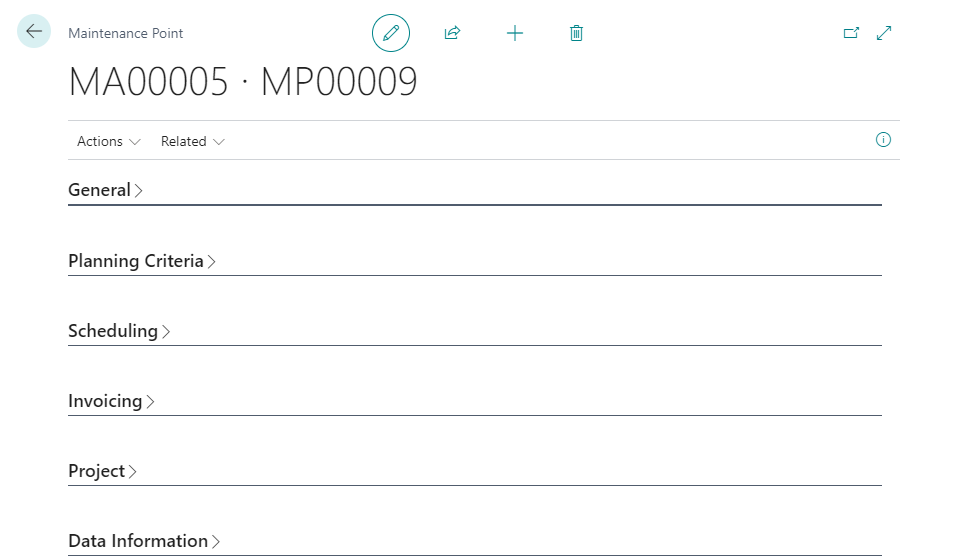

General

| Field | Description |

|---|---|

| No. | Specifies the maintenance point number. |

| Machine No. | Specifies the machine linked to the maintenance point. |

| Description | Specifies the description. |

| Work Request No. Series | Specifies the series number to use when creating work requests. |

| Resource No. | Specifies the resource to which the work request will be assigned. |

| Resource Group No. | Specifies the resource group to which the work request will be assigned. |

| Maintenance Type | Specifies the type of maintenance according to the UNI 10147 standard. |

| Maintenance Type Code | Specifies the maintenance type. (Classification) |

| Maintenance Work Type Code | Specifies the maintenance work type. (Classification) |

| Predicted Maintenance Time | Specifies the predicted maintenance time. |

| Planned Starting Time | Specifies the planned starting time. |

| Stop Production | Specifies if the production is stopped. (Information only) |

| Priority | Specifies the priority. |

| External Maintenance | Specifies if the maintenance is external. |

| Vendor No. | Specifies the vendor. |

| Blocked | Specifies if the maintenace point is blocked. |

| Maintenance Cycle No. | Specifies the No. of the Maintenance Cycle. |

| Maintenance Cycle Version | Specifies the version of the Maintenance Cycle. |

Planning Criteria

| Field | Description |

|---|---|

| Planning Criteria Code | Specifies the planning criteria. |

| Planning Value | Specifies the planning value. |

| Reached Value | Specifies the reached value. |

Scheduling

| Field | Description |

|---|---|

| Starting Date | Specifies the starting date. |

| Ending Date | Specifies the ending date. |

| Last Work Request Date | Specifies the date when the last work request was created. |

| Periodicity | Specifies the periodicity. |

| Next Date Due | Specifies the date when this maintenance point is next due. |

| Auto-Create Work Request | Specifies whether a new work request is automatically created when posting the previous work request. The user should create the first work request manually from the maintenance point. |

| Job Queue Scheduling | Specifies whether work requests are going to be automatically created via job queue. |

Invoicing

| Field | Description |

|---|---|

| Contract Reference No. | Specifies the contract reference number. |

Project

| Field | Description |

|---|---|

| Project No. | Specifies the Project No. |

| Project Task No. | Specifies the Project Task No. |

Data Information

Contains information about the creation date and the name of the user who created or made the last change.

Actions

Create Work Request

Create work requests according to the defined setup.

Learn more about automatic work request creation rules.

Copy Maintenance Point

Allows to create a copy of the maintenance point.

Comments

Allows to view or edit the comments of the maintenance point.

Spare Sparts

Allows to view or edit the spare parts of the maintenance point. Defined spare parts will be proposed in work requests.

PPE

Allows to view or edit the PPEs (Personal Protective Equipment) of the maintenance point. Defined PPEs will be proposed in work requests.

Work Request

Allows to view or edit the work requests of the machine and maintenance point.

Feedback

Was this page helpful?

Glad to hear it! Please tell us how we can improve.

Sorry to hear that. Please tell us how we can improve.