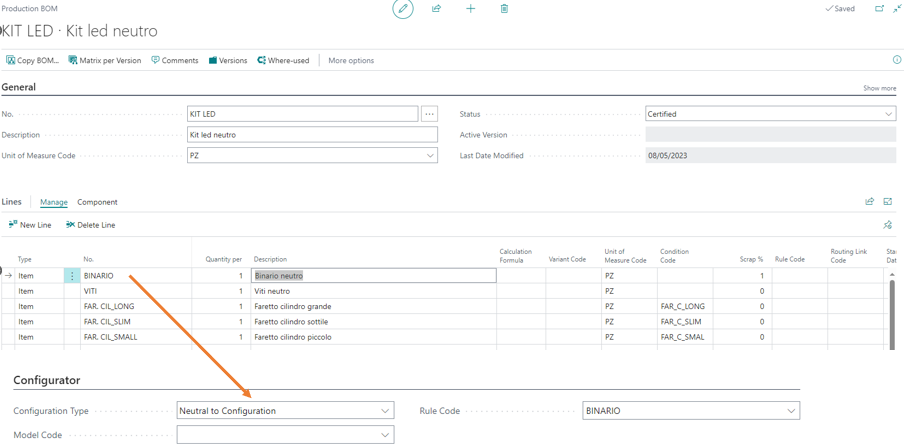

Production BOM

A production BOM is configurable when it is associated to an item with Configuration Type “Neutral to Configuration". The configuration process automatically creates a BOM for each new item configured (with “Production Order” replenishment system) as a copy of the neutral BOM.

If there is no configuration logic for individual rows in the BOM, the neutral BOM is modified without any changes.

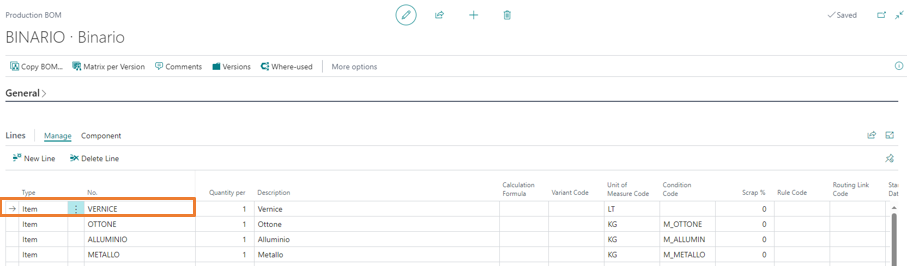

The lines in a BOM are configurable if:

- They contain “Neutral to Configuration” items;

- They contain “Neutral to Fix” items;

- They contain quantity formulas and/or conditions;

The first way to configure the lines of a production BOM is through the presence of configurable semi-finished products.

The configurator allows to automate the creation of the structure of an item, i.e. the automatic creation of semi-finished items, bills of materials and routings.

It is important to keep in mind that the configurator follows a “cascade” or top-down logic. Characteristics are always transmitted from the level 0 item to sublevels and never vice versa.

The transmission takes place in the following ways:

- Automatically: When the same characteristic exists in the secondary level as in the primary level. There is no need to establish logic.

- Default characteristics: When there is a characteristic in the secondary level that does not exist in the primary level and its value is always fixed.

- With «Higher level» relations: When there is a characteristic in the secondary level that does not exist in the primary level, and the logic must be defined.

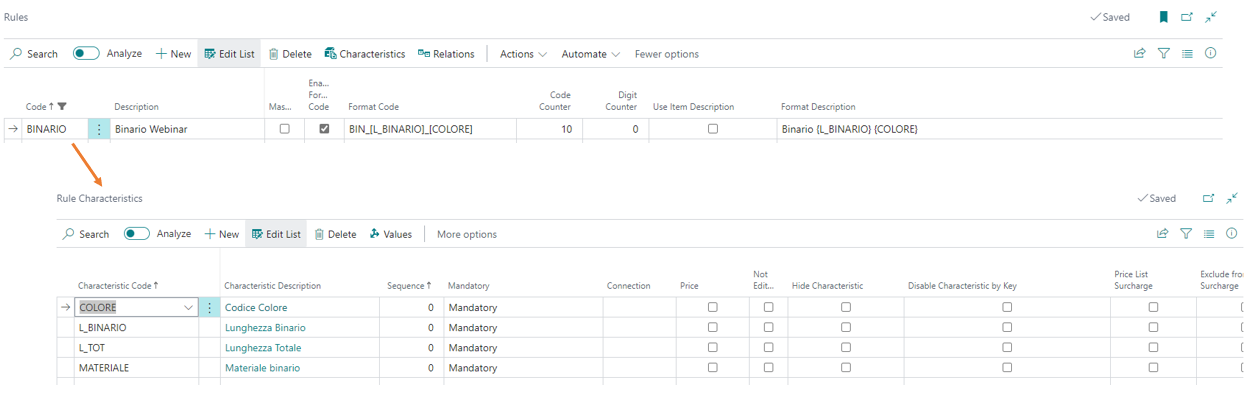

To have an item **automatically configured** by the configuration of the parent item it is necessary:

- Assign it a configuration type “Neutral to Configuration”;

- Assign it a rule that has an associated set of characteristics that could be a subset of those of the parent or even different (in which case higher level relations are required);

- Insert it into the BOM of the parent item.

Neutral Item

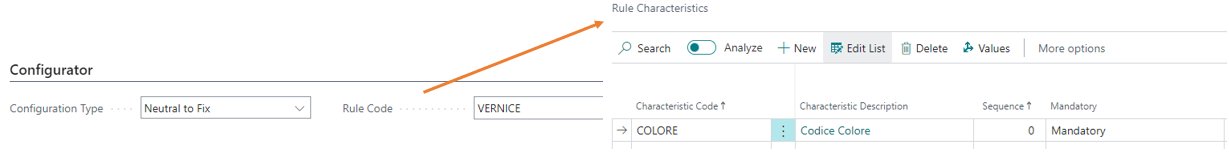

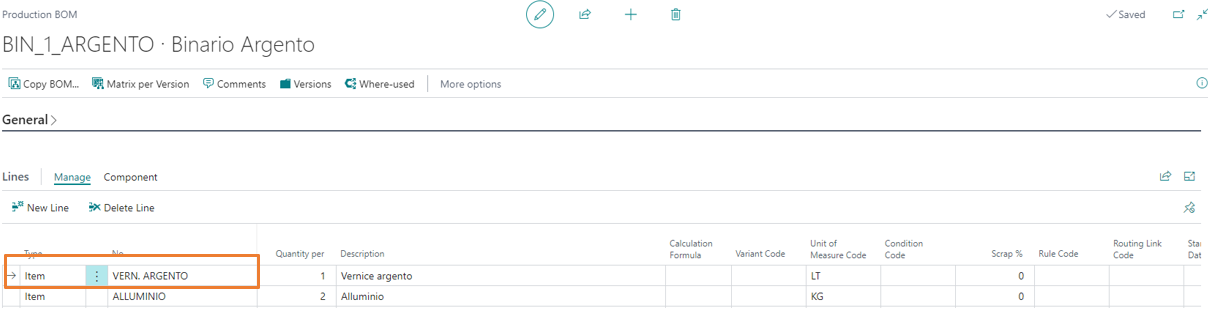

The second way to configure BOM lines is to use neutral items.

The ‘management of neutral items', the advanced level of which is the management of ‘neutral rules’ concerns the replacement of a fictitious item present in the configurable BOM with a more significant item in the BOM of the configured item.

Example: item “paint” without color that in the final BOM must be “red paint”.

NEUTRAL ITEM

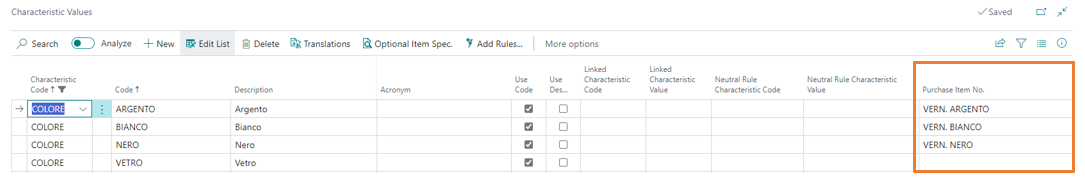

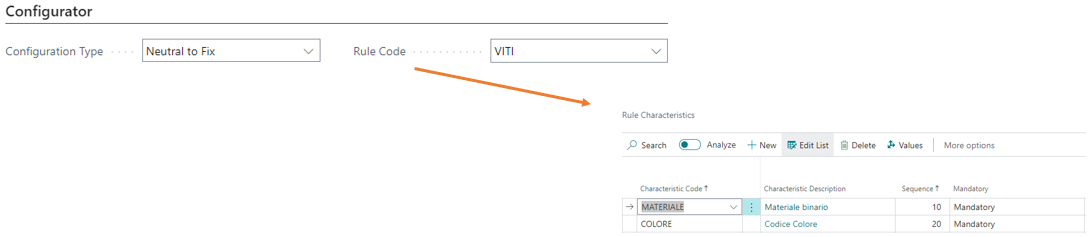

1 Create “From neutral to fix” item with an associated rule code having only the characteristics on which the choice of the definitive item depends

2 Within the Characteristic Values fill in the field Purchase item number with the item that must be replaced by the neutral item. In this case the ratio is 1:1 between characteristic value and item code.

3 Inside the configurable BOM insert the neutral item.

4 When configuring the configured item BOM, the system replaces the neutral item with the item, and the possible variant code, associated with the value of the chosen characteristic.

If the choice of the final item does not depend on a single value of a characteristic but on the combination of several values, neutral rules must be used.

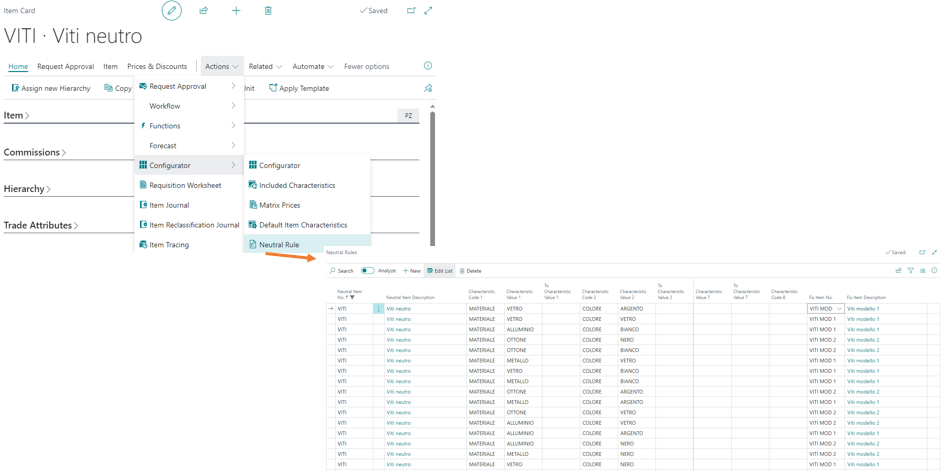

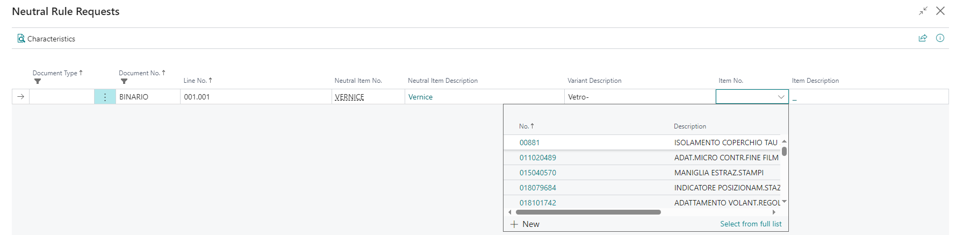

NEUTRAL RULES

1 The management of neutral rules is the same as the neutral item, so it is necessary to have an item “From neutral to fix” with an associated rule code that has only the characteristics on which the choice of the definitive item depends

2 From the neutral item, select the action “Neutral rules”.

3 Set all possible combinations of characteristics and values according to the sequence (this is important!) in which the characteristics are entered on the “Characteristic rules” page.

4 In the “Fix item no." field, indicate which item number must be substituted for the neutral item in the BOM of the configured item. The neutral rule also allows to indicate a possible variant code in the Fix variant code field.

ENABLE NEUTRAL REQUEST

Activating the Enable neutral requests option in CFG setup ensures that, in the absence of a neutral rule that satisfies the configuration, a page must be opened while configuring to insert a new neutral rule and “teach” the configurator a new setting.

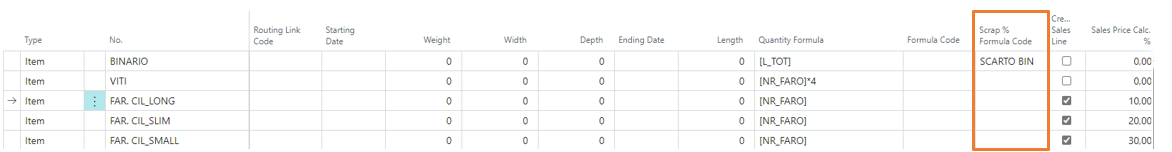

Formulas and condition

The third way to configure BOM lines is to use conditions and formulas for calculating the “Quantity per” and “% scrap” fields. These settings can be used in combination with rows containing items such as “Fix” (non-configurable), “Neutral to Configuration” (configurable semi-finished products) or “Neutral to Fix” (neutral items).

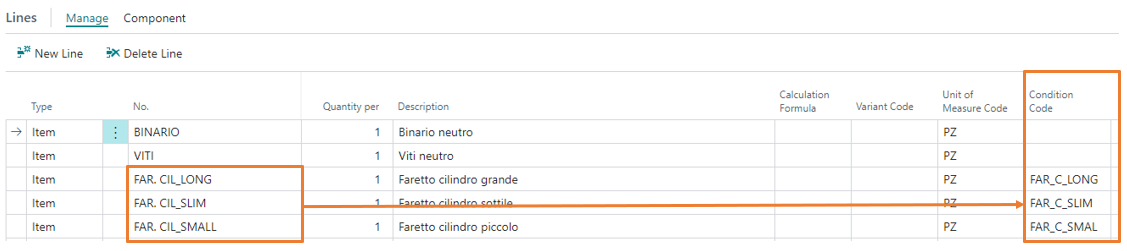

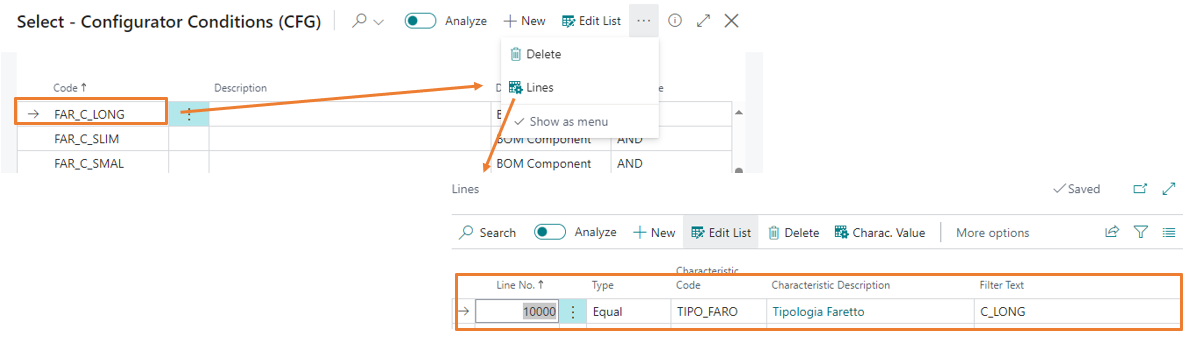

CONDITIONS FOR SELECTING BOM LINES

Inserting a condition code on a BOM line means that in the configured BOM the line in question will only be present if the entries expressed in the condition code are true. Otherwise, the line will not be included.

For example, the line containing the item «FAR. CIL_LONG» will be inserted into the final BOM only on condition that the «TIPO_FARO» takes on the value «C_LONG».

WARNING: This method is the easiest to set up, but it’s also the one that could increase the number of BOM lines created.

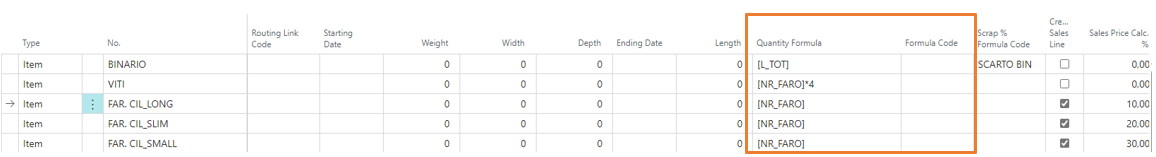

FORMULAS FOR QUANTITY CALCULATION

The “Quantity per” field of the final BOM may have to depend on the value of some characteristics, especially those of type measure. For this reason, calculation logics can be indicated in the “Formula quantity” and “Formula code” fields.

The “Formula quantity” field is used to express simple calculations. Entering a characteristic code (always in square brackets [CHARACTERISTIC CODE]) means taking into consideration the value that the specified characteristic will assume during configuration.

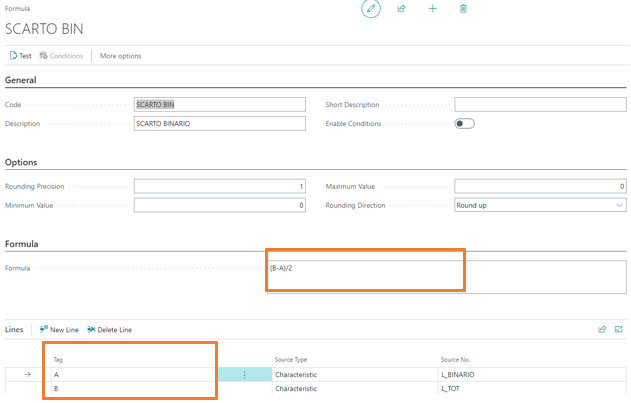

In the “Formula code” field, you can assign a formula that contains more complex logic.

The "% scrap" field can also be conditioned according to a formula entered in the “**scrap % formula code**" field.

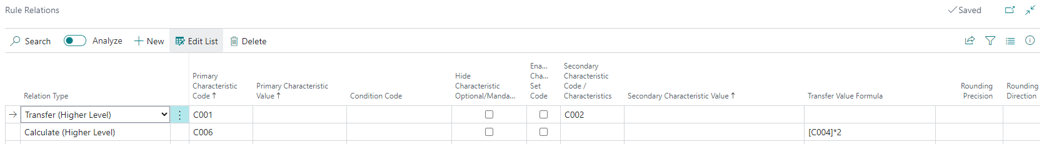

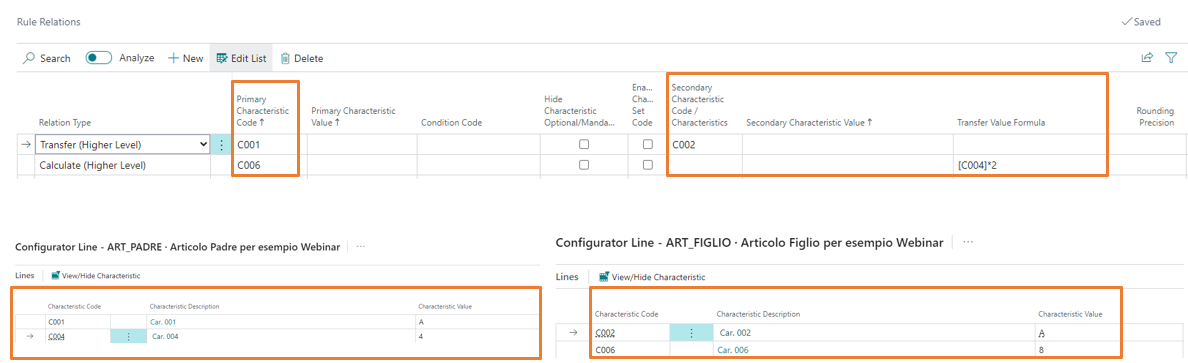

Higher Level Relations

Higher level relations are used when:

- The child item has characteristics that are not present in the parent item (otherwise the transfer of values would happen automatically)

- Characteristic mappings are required (interaction between characteristics must occur between parent and child)

NOTE: Higher level relations occur only between configurable items (type: neutral to configuration).

You can condition the configuration of a child item based on the configuration choices of the parent item.

- The parent item must be a CONFIGURABLE item

The child item must be a CONFIGURABLE item

The values that the child item inherits from the parent item must be set in the configuration rules.

- The value transfer from the higher level, transfers the value of the characteristic from the higher levels (going up the BOM tree) to the child article;

- The calculation from higher level can involve characteristic formulas configured in higher levels.

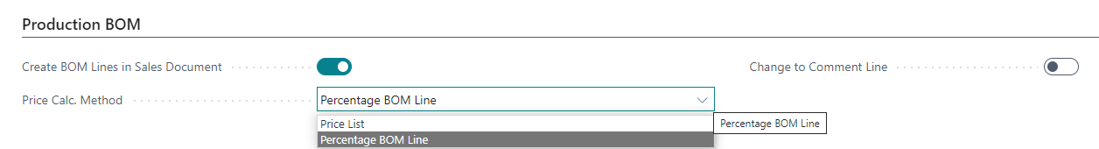

Create BOM Lines in Sales Document

Items involved in the BOM can be a pricing tool.

To manage them, the functionality in the Configurator Setup must be enabled through the Create BOM Lines in Sales Document flag.

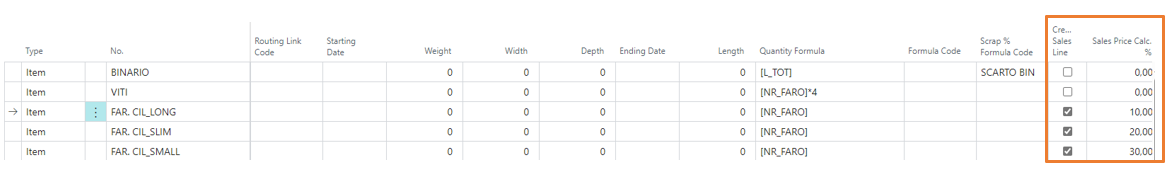

The prices of the generated lines can be calculated using the Price Calc. Method option:

- Price List: The price is derived from the sales prices.

- Percentage BOM Line: The price of the individual components is calculated using a percentage in the production BOM lines.

The Change to Comment Line field, if enabled, “transforms” the line with the neutral item from which the configuration was launched into a comment.

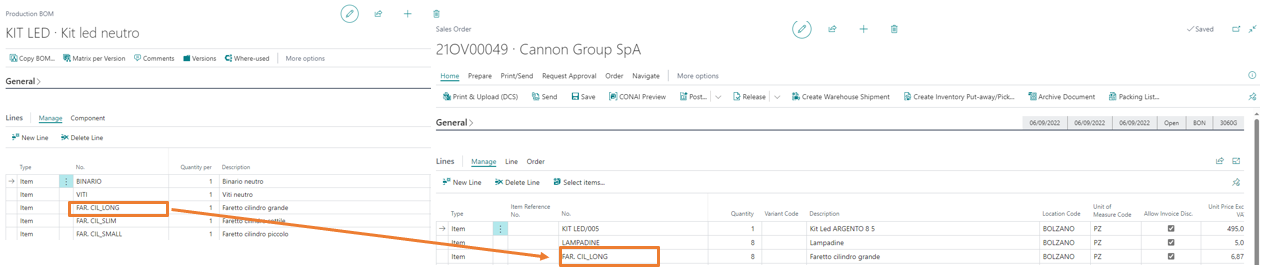

In the production BOM lines, you can define which components should generate a line in sales documents.

It is also possible to define the percentage with which to calculate the sales price (percentage of the configured item price excluding surcharges).

In a sales document, the configurator generates the additional rows taken from the first level of the production BOM.

Any neutral items are configured and any associated surcharges / optionals are generated.

Feedback

Was this page helpful?

Glad to hear it! Please tell us how we can improve.

Sorry to hear that. Please tell us how we can improve.