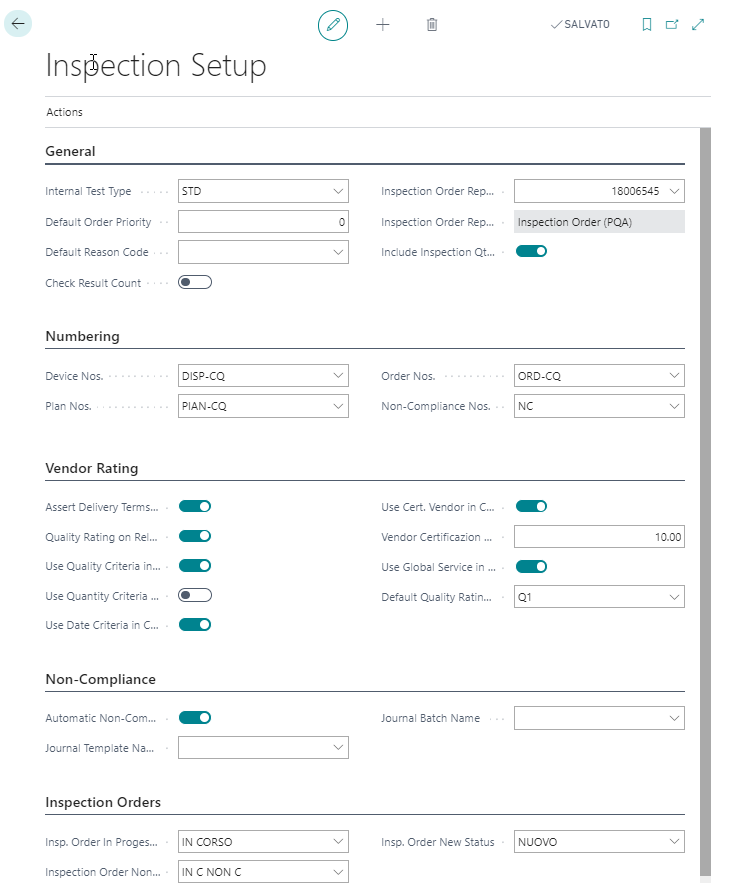

Inspection Setup (PQA)

In the Inspection Setup page you can specify the information required by the system to perform the checks.

General

In the table below are listed the fields to fill in:

| Field | Description |

|---|---|

| Internal Test Type | Choose the test type. The test types and their codes are set in Test Types (PQA) (see specific section below). |

| Default Order Priority | Specifies the priority of new inspection order created from receipt |

| Default Reason Code | Specifies the Inspection order reason code |

| Check Result Count | Verify that the results are at least the same number as the sample size |

| Inspection Order Report ID | Specifies the Inspection Order Report |

| Inspection Order Report Name | Specifies the Inspection Order Report name |

| Disable Production Output Transfer in Quality | If enabled, the quantity transfer to the quality inspection bin is not performed when posting the production output. |

| Include Inspection Qty. in MRP | Specifies if Inspection Qty. is included on MRP. If you disable the option the quantity is calculated as ItemLedgerEntry.RemainingQuantity-ItemLedgerEntry.InspectionQuantity. |

Numbering

In the table below are listed the fields to fill in:

| Field | Description |

|---|---|

| Device Nos. | Specifies the code of the number series that will be used when creating Device |

| Plan Nos. | Specifies the code of the number series that will be used when creating Plan |

| Order Nos. | Specifies the code of the number series that will be used when creating Inspection Order |

| Non-Compliance Nos. | Specifies the code of the number series that will be used when creating Non-Compliance document |

Vendor Rating

In the table below are listed the fields to fill in:

| Field | Description |

|---|---|

| Assert Delivery Terms on Release | Activate the check on late payments when counting the vendor rating, |

| Quality Rating on Release | Activate the Quality management when counting the vendor rating, |

| Use Quality Criteria in Calc. | Specifies that the system will use quality criteria in rating calculation |

| Use Quantity Criteria in Calc. | The system uses quantity criteria in rating calculation |

| Use Date Criteria in Calc. | Specifies that the system will use Date criteria in rating calculation |

| Use Cert. Vendor in Calc. | Specifies that the system will use certificate Vendor in rating calculation |

| Vendor Certification Value | Specifies the vendor certification value for rating calculation |

| Use Global Service in Calc. | Specifies if global service is to use in calculation |

| Default Quality Rating Code | Specifies the default quality rating code |

Non-Compliance

You need to fill in:

| Field | Description |

|---|---|

| Automatic Non-Compl. Creation | Specifies if create automatic non-Compl. when the result of quality is not satisfactory |

| Journal Template Name | Specifies the Default Journal Template Name |

| Journal Batch Name | Specifies the Default Journal Batch Name |

Inspection Orders

You need to fill in:

| Field | Description |

|---|---|

| Insp. Order In Progess Status | Specifies Insp. Order In Progess Status |

| Insp. Order Non-Compliance Status | Specifies Insp. Order with Non-Compliance Status |

| Insp. Order New Status | Specifies Insp. Order New Status |

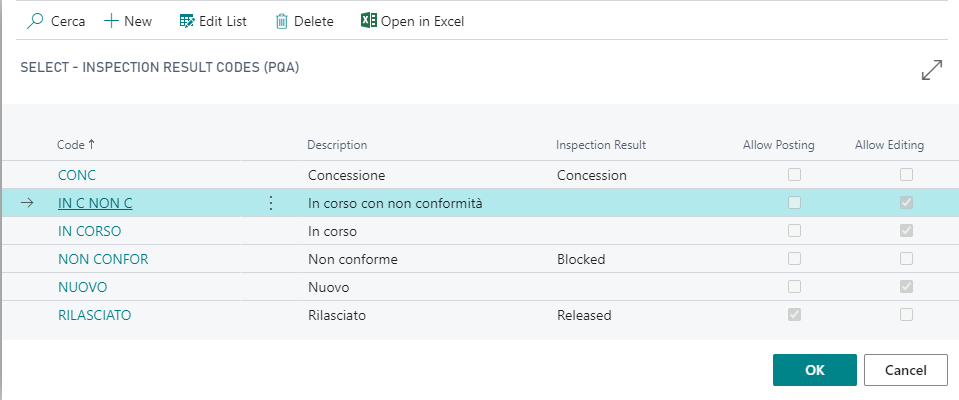

Inspection Results Codes (PQA)

This table allows you to manage test results with a code:

| Field | Description |

|---|---|

| Code | assign a name for the result code |

| Description | enter a description |

| Inspection Result | • Released: the goods are therefore no longer blocked for inspection but are free to be consumed or shipped. • Concession: a part of the goods could be usable and a part is not compliant therefore a reclassification of the goods will be made in a setup area in the location. • Blocked: the goods are non-compliant therefore a reclassification of the goods will be made in a setup area in the location. |

| Allow Posting | flag that authorizes subsequent postings of the source document: for example, with a partially received receipt, if you wish to continue receiving the goods, any previously inspection orders must be in a status that allows posting, otherwise subsequent postings are not permitted. |

| Allow Editing | allows you to make changes on the inspection order card |

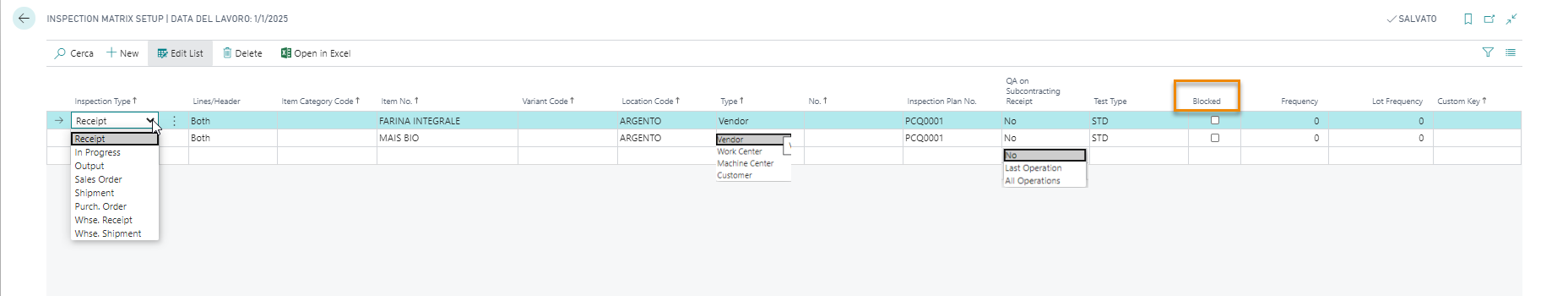

Inspection Matrix Setup (PQA)

This setup allows you to decide when is to create an automatic inspection order. After generating a setup line it is possible to disable it, if necessary with the flag Blocked.

| Inspection Type | Description |

|---|---|

| Receipt | Used for warehouses with and without warehouse. When the loading document is recorded, from a purchase order or whse loading, a quality control order will be created automatically. |

| In Progress | Used in case of multiphase cycles. In a production order, when the capacity ledger entry is posted, a quality control order will be created automatically. |

| Output | In a production order, when posting the item ledger entry, a quality control order will be created automatically. If X deposits are made, X control orders will be created. |

| Sales Order | Used for warehouses without warehouse management. The app allows you to detach a quality order from a sales order. |

| Shipment | Used for warehouses without warehouse. The app allows you to detach a quality control order from the registered sales shipment, to be activated via custom. |

| Purch. Order | Used for warehouses without warehouse. Before registering the loading document, the app allows you to detach a control order from the purchase order. This typology defined as «incoming control» is typical of the food sector as the checks on the truck are carried out before the goods are accepted. |

| Whse. Receipt | Used for warehouses with warehouse management. Before posting the loading document, the app allows you to detach a quality control order from the whse load. As mentioned above, this typology is defined as «input control». |

| Whse. Shipment | Used for warehouses with warehouse management. The app allows you to detach a quality order manually from the whse shipment. |

Once defined the inspection type you need to specify filters in order to choose the particular conditions for checks. It is possible to filter by:

Item Category Code

Item No.

Variant Code

Location Code

Test Type

In “Type” and “No”. field you can filter by:

Vendor: if Inspection Type is “Receipt”

Work Center: if Inspection Type is “In Progress”

Machine Center

Customer

“QA on Subcontracting Receipt“ specifies whether that matrix setup is also active for subcontracting production order:

| Name | Description |

|---|---|

| LAST OPERATION | it is active only if subcontracting is the last phase of the production order |

| ALL OPERATIONS | it is active in all phases of the production order |

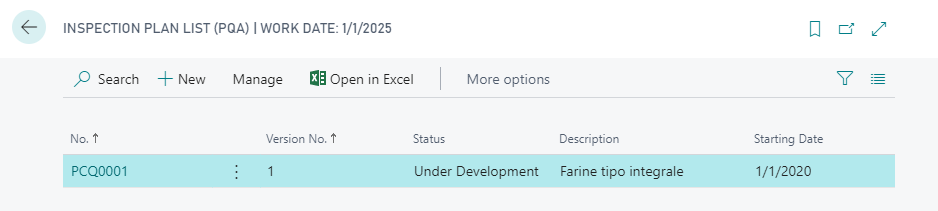

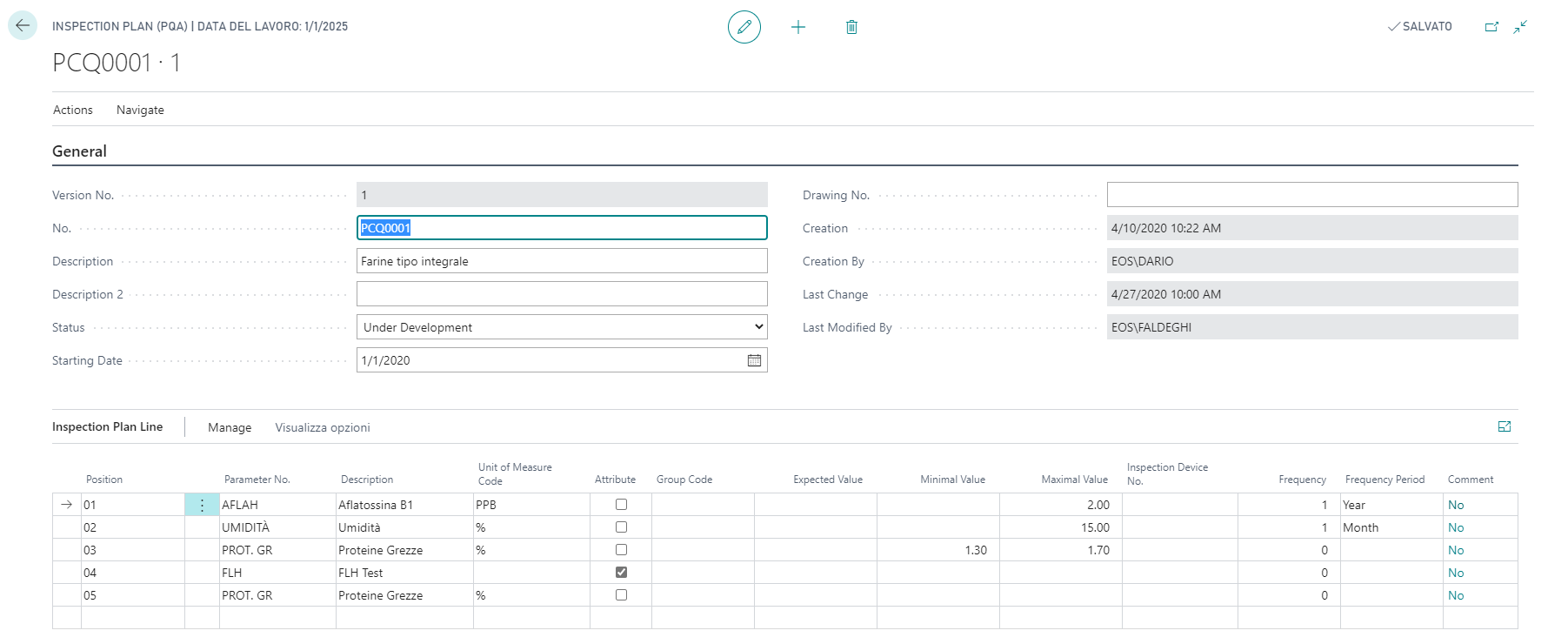

Inspection Plan List (PQA)

In this page we need to define which is the inspection plan to be used and its frequency.

From New it is possible to create a new inspection plan in which you need to specify parameters to be considered while testing goods and also you need to enter the expected values. Then you can choose the devices to be used in the checks. See Planning.

Frequency

This field is used if you want to assign a frequency to the row.

Options:

0 = The Inspection Plan is always performed

1 = The Inspection Plan is performed on the basis of the specified frequency in the field “Frequency Period”

The Frequency Period is: day, week, month, quarter, year

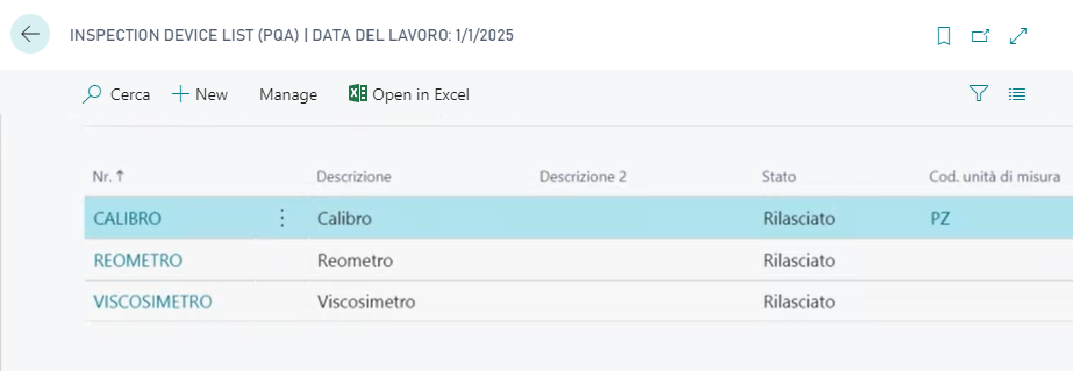

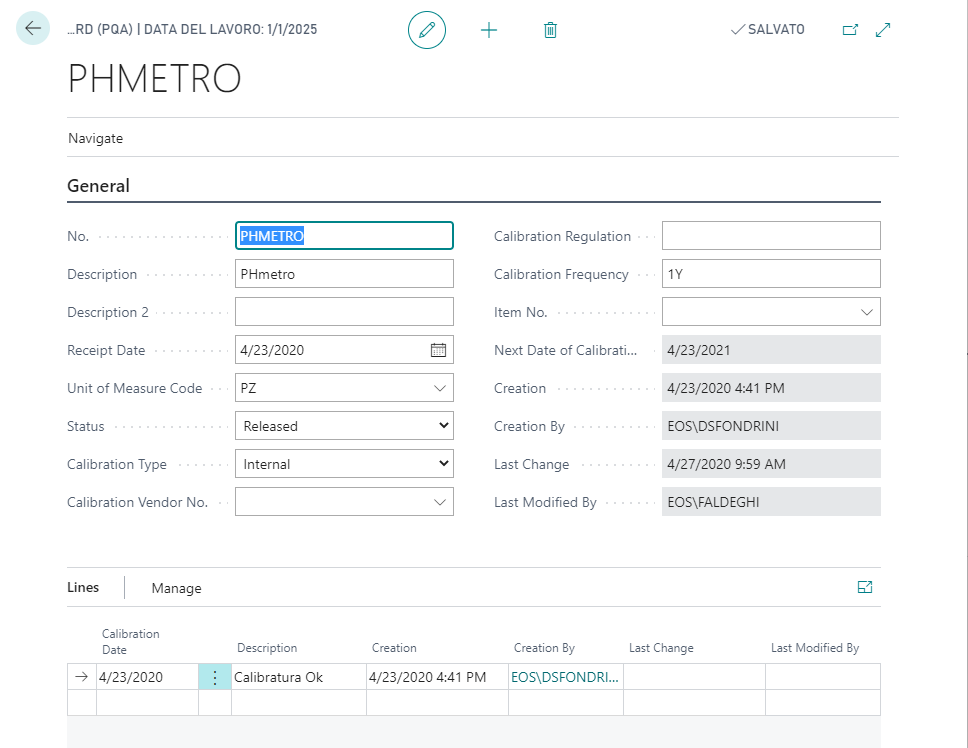

Inspection Device List (PQA)

On Inspection Device List (PQA) page, from “New”, you can define the mechanical devices that will be used during the checks. The following table shows the key fields displayed in the page:

| Field | Option | Description |

|---|---|---|

| Unit of Measure Code | To insert the unit of measure code used by the device | |

| Calibration Type | Internal / External | It indicates who performs the calibration (if it is made by the company itself or by a specialized company.) |

| Status | Under Inspecton | If the device is in the calibration phase. |

| Status | Released | If the device has been calibrated and can be used to perform quality checks. |

| Status | Blocked | If the device is out of calibration and can not be used for measurements. |

| Calibration Frequency | Indicates how often the device must be recalibrated (eg. 1A = 1 year) | |

| Item No. | The device can be linked to an item | |

| Next Date of Calibration | It indicates the expected date of re-calibration of the device |

In the Lines you can view the history of the calibrations performed.

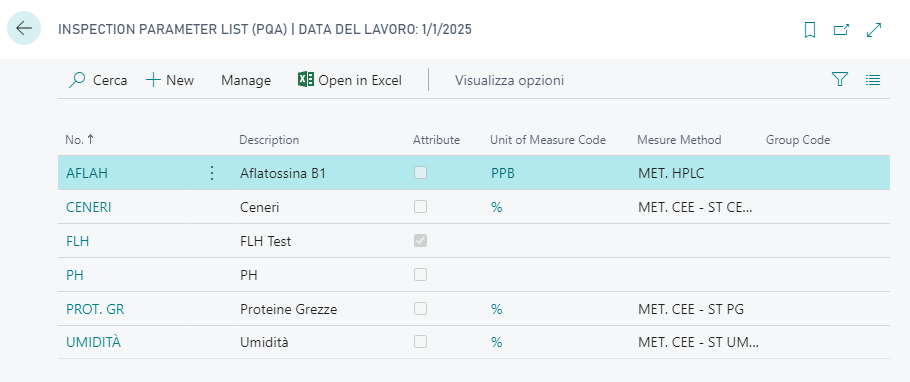

Inspection Parameter List (PQA)

Here you can set the parameters to be used to carry out the checks. From New you can enter a new parameter.

Measurable: parameters that require measurable detection.

Attributes: parameters that do not require measurable detection.

Attributes can have different parameter types:

Actual value: deprecated

Parameter attribute code: the analysis can give different and tabular results (e.g. yellow, green, red colour…)

Attribute Fulfilled: the analysis can be positive or negative

It is possible to define the unit of measurement in Unit of Measure Code and possibly the Measure Method.

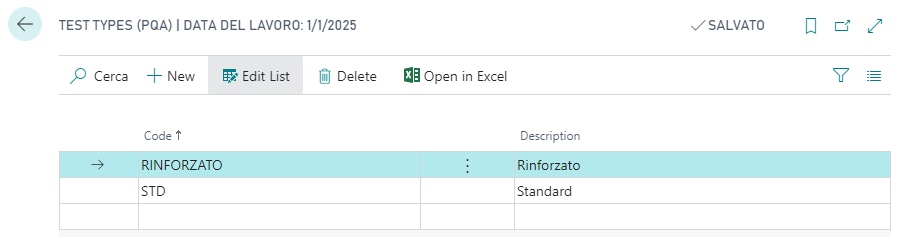

Test types (PQA)

In Test Types (PQA) it is possible to define the test types entering the fields “Code” and “Description”:

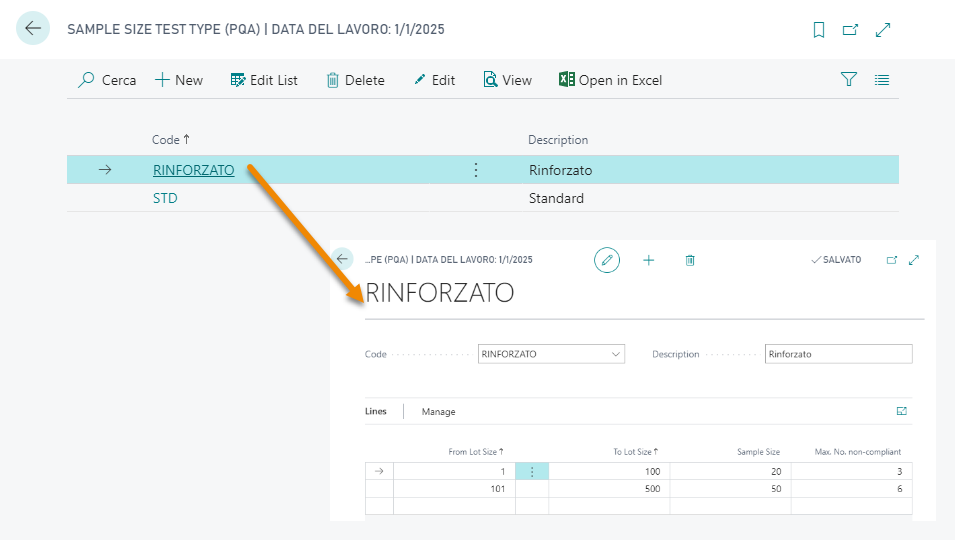

Sample Size Test Type (PQA)

In Sample Size Test Type (PQA) you can specify the dimension of the samples to be tested and the number of pieces that may be non-compliant:

Example: we create a purchase order, form Lines->Product Quality Assurance we choose Create Inspection Order. The system will open the Inspection Order page where the field relative to the sample size to be checked will be already populated by the system, on the basis of the Sample Size Test Type (PQA) table.

| NB |

|---|

| The field Sample Size is in the Inspection Matrix Setup (PQA), in the Vendor Card and in the Inspection Setup (PQA). Priority: the system verifies the value in the matrix setup, if blank it passes to the vendor card, if blank the system passes to the inspection setup. |

Other setups

Blocked Locations

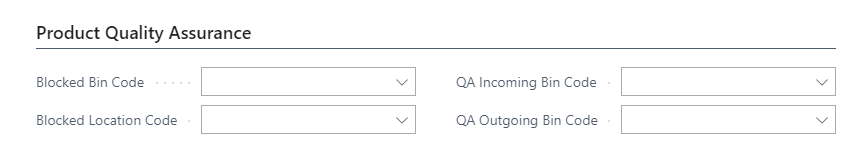

In Locations, tab Product Quality Assurance you can decide where to place the non-compliant goods:

| Field | Description |

|---|---|

| QA Incoming Bin Code | Define here what is bin in which must be deposited the goods that enter into PQA control. |

| QA Outgoing Bin Code | Enter the bin in which must be deposited the goods resulted non-compliant. |

| Blocked Location Code | It is the location to whitch the goods will be automatically moved if not compliant. |

| Blocked Bin Code | Specify the bin to which the goods will be automatically moved if non-compliant. |

Feedback

Was this page helpful?

Glad to hear it! Please tell us how we can improve.

Sorry to hear that. Please tell us how we can improve.